5 Myths About Refinery Safety

Table of Contents

Introduction – Why Refinery Safety Deserves a Reality Check

Refinery operations in the oil and gas industry are inherently high-risk, where even minor errors can lead to catastrophic outcomes. Despite regulatory compliance efforts, serious incidents persist, highlighting the need for a deeper safety overhaul.

The 2005 BP Texas City explosion, which killed 15 people, occurred despite OSHA compliance, exposing systemic failures in operational practices—a pattern echoed in the 2012 Chevron Richmond fire, where corrosion and leadership breakdowns contributed to the disaster Chemical Safety Board (CSB). According to the U.S. Chemical Safety Board, over 50% of refinery incidents stem from systemic—not frontline—failures, including poor maintenance, miscommunication, and weak safety architectures.

Global losses from such incidents amount to billions annually, making it imperative to embrace structured Process Safety Management (PSM), as outlined by the American Petroleum Institute (API)

This sets the stage for dispelling persistent safety myths in refining, each rooted in outdated assumptions that need urgent revisiting.

Myth #1 – “Compliance Equals Safety”

Why It’s a Myth

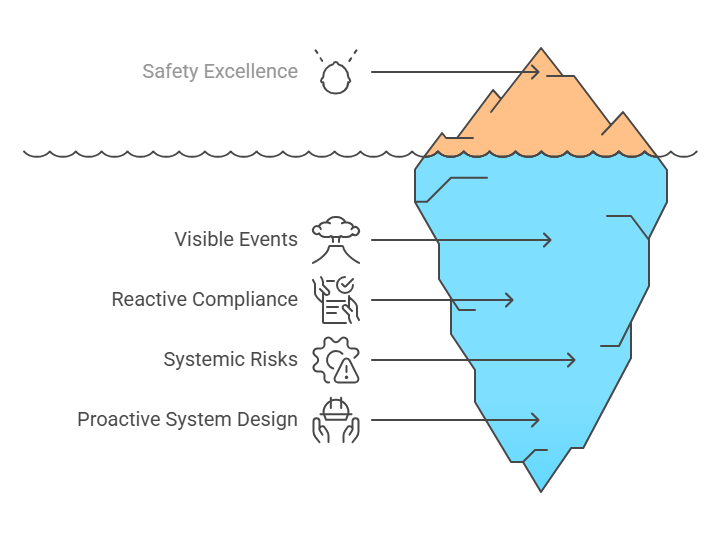

One of the most persistent misconceptions is equating compliance with safety excellence. The National Safety Council (NSC) notes that compliance is reactive and ensures only minimal legal standards, not operational robustness.

BP Texas City was OSHA-compliant at its explosion, yet systemic lapses in hazard recognition and procedural enforcement led to catastrophe. The Energy Institute (UK) reinforces this with case studies of compliant facilities that failed catastrophically.

The Reality

True safety comes from proactive system design. As McKinsey detailed, high-reliability organizations integrate real-time analytics, continuous improvement, and predictive frameworks well beyond regulation.

The Center for Chemical Process Safety (CCPS) advocates risk-based approaches, in which leading indicators, cross-functional safety audits, and culture-building are integrated.

See Myth #1 in our refinery safety framework to explore how compliance-only approaches fail in dynamic environments.

Myth #2 – “Incidents Only Happen Due to Human Error”

Why It’s a Myth

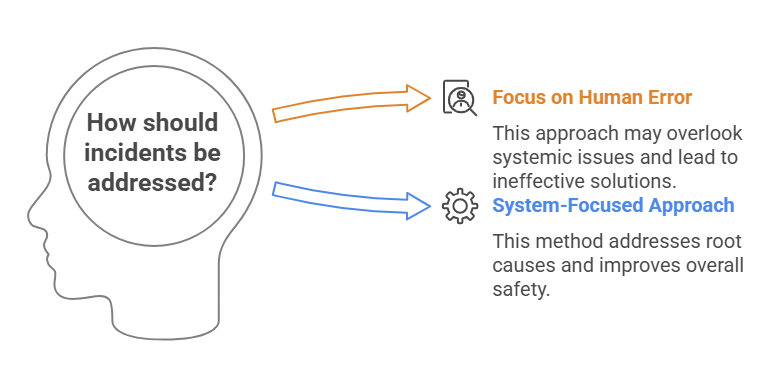

Blaming frontline staff for incidents ignores broader systemic realities. According to NIOSH, human error is more often a symptom of poor system design than individual failure.

The Human Factors and Ergonomics Society (HFES) supports this, noting that 80–90% of errors stem from unclear expectations, poor interface design, fatigue, or inadequate training.

The Reality

Safety stems from an organization’s ability to learn from and adapt to failure. In Harvard Business Review, system-based approaches are shown to outperform blame-focused models.

Sidney Dekker’s Field Guide to Understanding Human Error reframes errors as system-induced, highlighting the need for design thinking and operational empathy.

Take the Bhopal disaster: far from a single-point failure, it revealed widespread breakdowns in maintenance, training, and monitoring protocols—the same themes repeated in modern refinery incidents.

Read Myth #2 from our framework for a deeper dive into how systems thinking transforms safety culture.

Myth #3 – “More Alarms Mean More Safety”

Why It’s a Myth

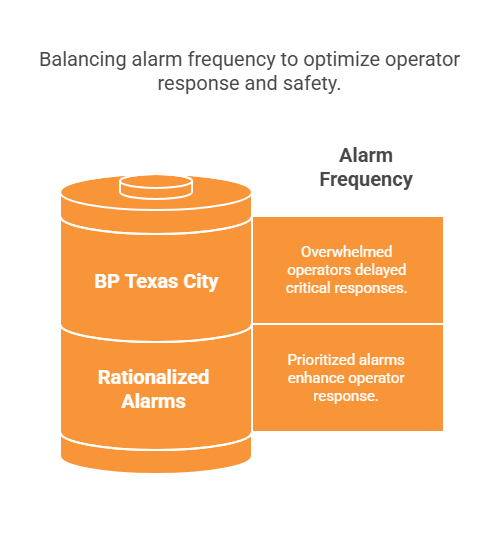

Alarms are a safety staple, but quantity can overwhelm rather than assist. The ISA 18.2 Alarm Management Standard warns against “alarm floods” that desensitize operators and delay critical responses.

During the BP Texas City explosion, 200+ alarms were triggered within minutes, overwhelming operators with noise and chaos. OSHA correlates this to cognitive overload, rendering even well-trained staff ineffective during crises.

The Reality

Alarm systems should be intelligent, filtered, and prioritized. Honeywell advocates for alarm rationalization strategies, while the ARC Advisory Group emphasizes tiered alarms and dynamic suppression during transitional phases.

For complete analysis, revisit Myth #3 on the risks of unchecked alarm saturation.

Myth #4 – “Experienced Operators Don’t Need Ongoing Safety Training”

Why It’s a Myth

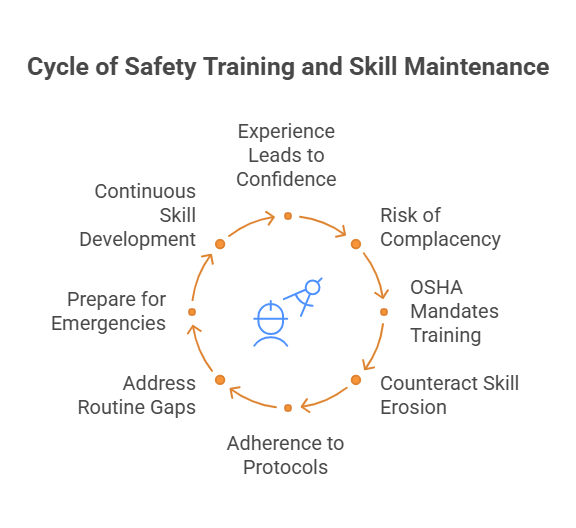

Experience brings confidence, but also procedural shortcuts and drift. OSHA mandates ongoing refresher training to combat complacency and skill erosion.

The CCPS shows that over 60% of experienced operators routinely skip steps unless retrained. Habituation to routine tasks often leads to gaps in protocol during non-routine or emergency events.

The Reality

Modern training is scenario-based and simulation-driven. Energy Safety Canada has led the shift toward immersive platforms that simulate real-world failure modes for both new and senior teams.

OMS Academy supports this evolution with refinery-specific eLearning platforms combining role-based simulation, procedural requalification, and failure-mode training, ensuring teams are prepared rather than experienced.

Dive deeper into Myth #4 for insights on how even veterans need training evolution.

Myth #5 – “Digital Tools Make Plants Less Safe

Why It’s a Myth

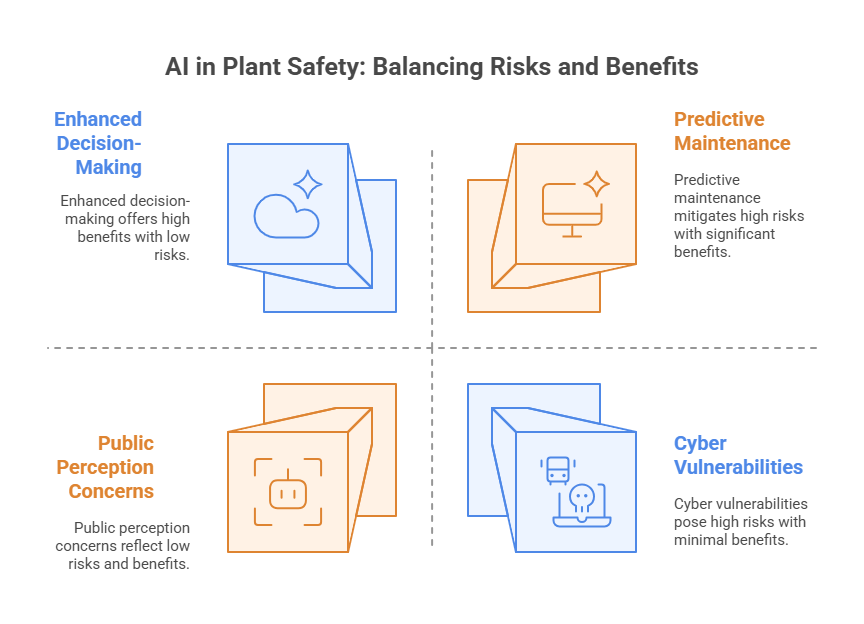

As AI and automation spread across refining, some fear a loss of human control and increased cyber risk. CISA warns of growing digital vulnerabilities, while public perception remains wary of black-box algorithms.

However, Harvard Business Review debunks the notion that digital means disengagement. Properly deployed, AI frees operators from repetitive tasks and enhances decision clarity.

The Reality

AI isn’t replacing operators—it’s augmenting safety. GE Digital’s APM uses predictive maintenance to detect faults days in advance, reducing downtime and incident likelihood.

OMS Solutions integrates diagnostic AI in movement automation, reconciliation, and blending. In one documented case, AI detected abnormal vibration in a pump, averting a $250K shutdown.

Explore Myth #5 to see how digital transformation strengthens refinery safety.

Conclusion – Safety Is a Living System, Not a Static Score

Safety isn’t static in chemical engineering and oil refining—it’s systemic. As aging assets, digital disruption, and workforce transition reshape the industry, the key to resilience lies in adaptive learning, reflective teams, and continuous challenge of outdated assumptions.

The Lean Enterprise Institute promotes daily problem-solving routines that keep safety dynamic. Harvard Business Review encourages organizational adaptability through improvisational leadership and feedback-rich environments.

For refinery leaders, the next step isn’t just more technology—it’s more clarity, culture, and capability. Resources like OMS Academy offer a digital-first path to building competency across the operator lifecycle.