Products

OMS does not offer any software of its own but offers services to custom develop and/or integrated third party systems to design, develop, commission, train users and provide end-user support for the automation of refinery offsite operations. OMS has provided the documents on our website for the education of reader and offer consulting services to implement and integrate any of the systems mentioned here in your refinery or plant.

These refinery products and systems are categorized and discussed here on this page with clickable details to follow. Each oil and gas products has the following documents:

- Informative Datasheet

- PowerPoint demo

- White papers

- OMS Webinar

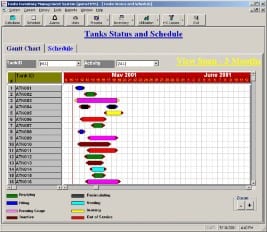

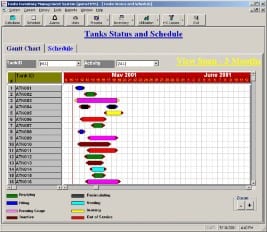

Tank Management

A typical refinery tank farm consists of 100‐300 tanks of large capacities to store crude oil and manufactured products. These are refinery’s assets of the value of billions of water and constantl

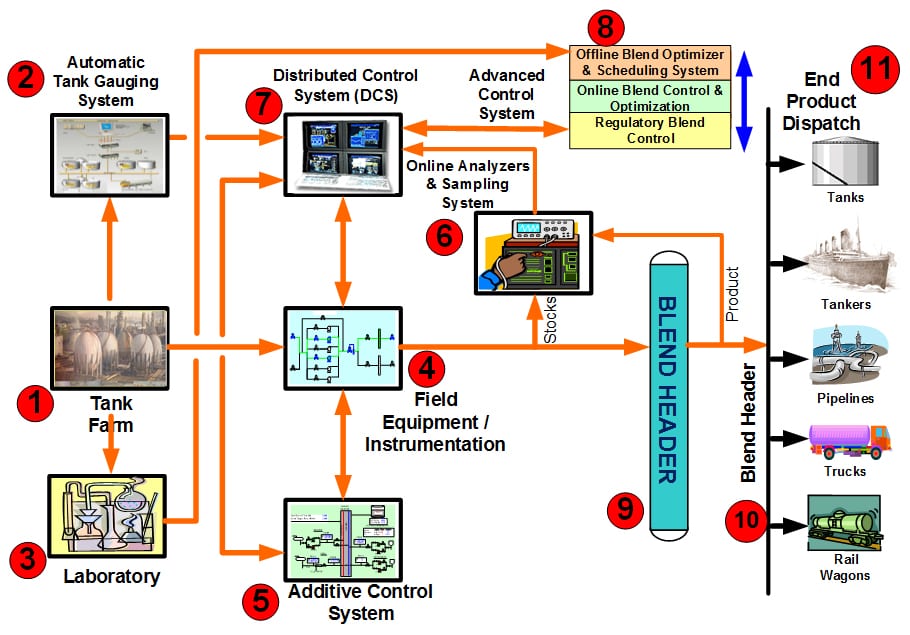

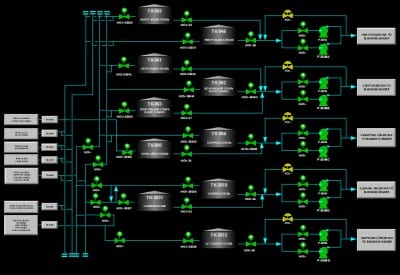

Material Movement & Control System

A typical refinery executes daily 100-300 material movements tasks in 12-15 types. It is very man-power intensive and has safety risks. Hence, refinery commissions oil movement control and management

Crude Blending

The refinery is usually designed to operate on a certain type of crude oil in terms of its properties. However, over decades the crude oil qualities change even from the same source and also are limit

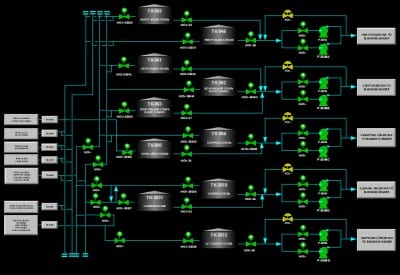

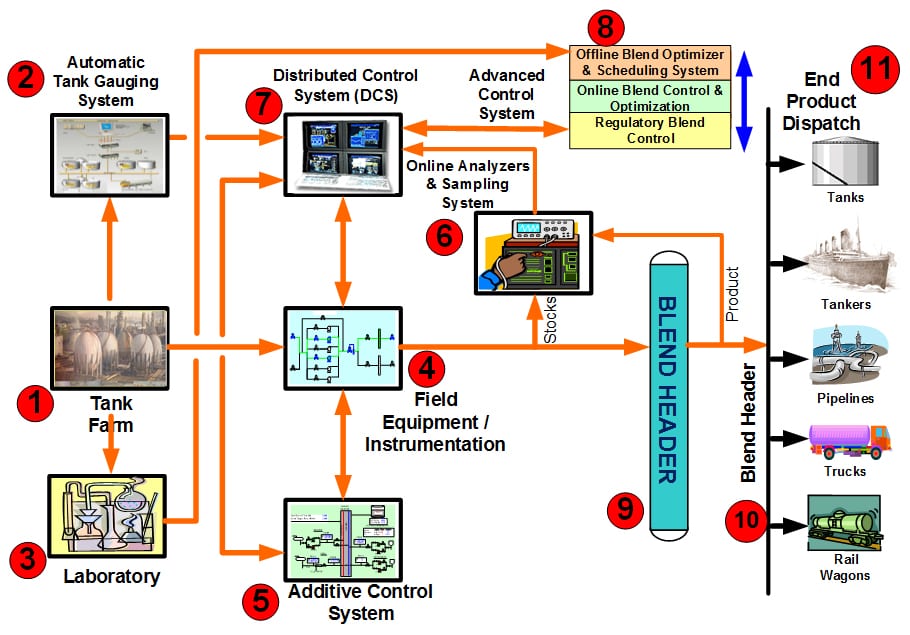

Fuels Blending Systems

Typically 70-80% of one barrel of crude oil produces fuels such as gasoline, diesel, fuel oil, Kerosene, LPG etc. Fuels products are produced by blending 10-12 products with different properties. This

Blending Information System

Execution of a single fuel blend produces tremendous amount of data such as blend batch details, component qualities and flows, tanks inventory in real-time. more. Typical 300+ batches are executed ye

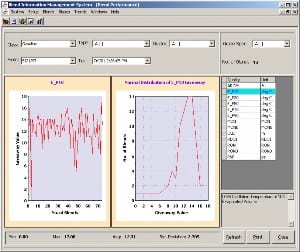

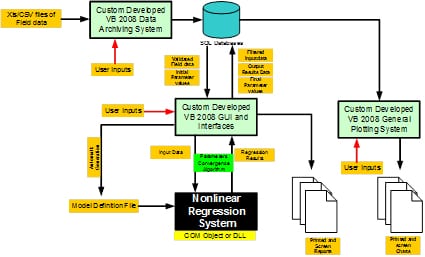

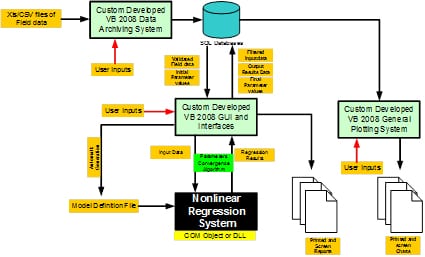

Blending Qualities Models & Regression

Fuels blending models, both linear and non-linear, have parameters which are required to be customized for a specific refinery as each refinery configuration and blending components are different. Gen

Blending Economics Estimator

Normally, the economics of upgrading a fuels blending system from manual blending is based on the estimation of blend qualities giveaways using one years worth blend data. The OMS Blends economics Est

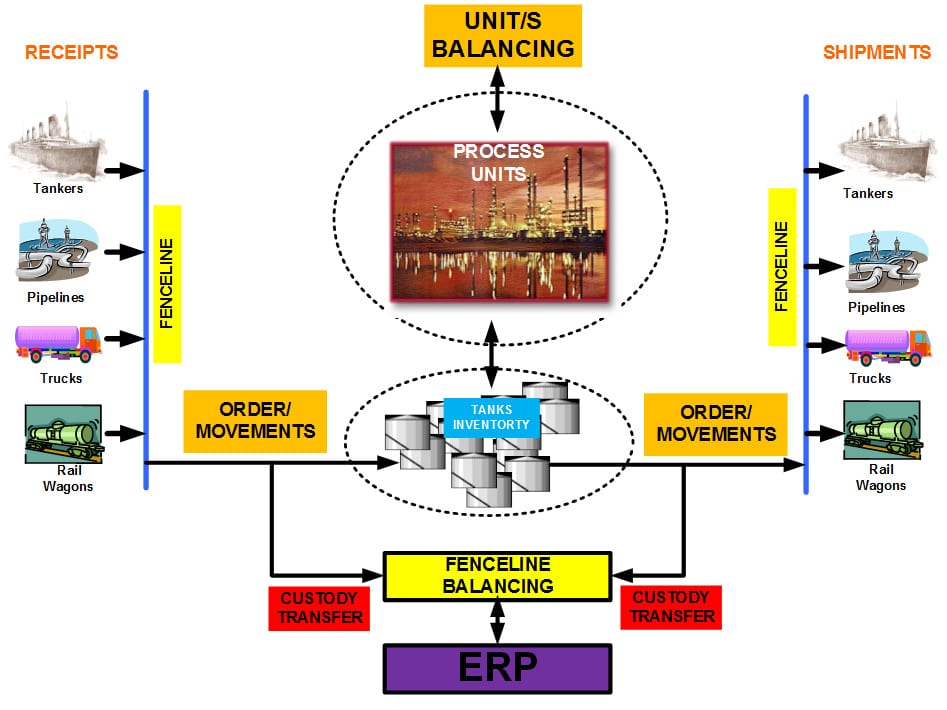

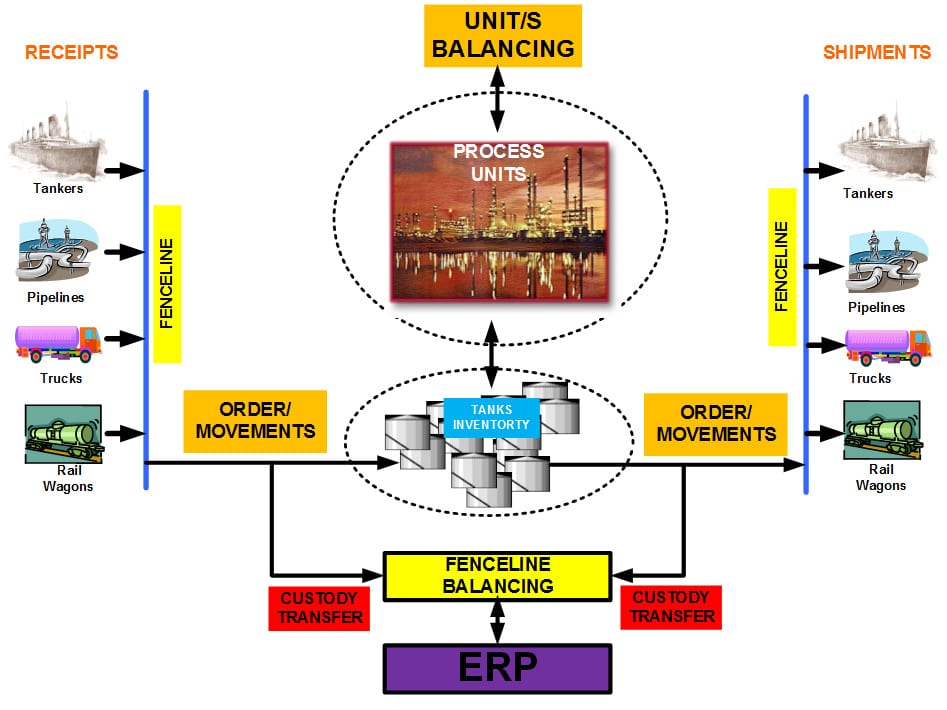

Hydrocarbon Management

The term Hydrocarbon management or mass reconciliation or oil loss all mean to the balancing of the input and output of a refinery. The typical best run refineries average imbalance is between 0.35-0.