Upskilling 360: 7 Reasons It’s the Smartest Investment Your Refinery Can Make

Table of Contents

In today’s complex and high-risk refinery landscape, upskilling isn’t a nice-to-have—it’s a strategic must. This article explores the hidden financial risks of ignoring workforce development and shows how smart training investments can protect margins, boost resilience, and future-proof assets. From operational errors to compliance penalties, the costs add up quickly. So, the real question is: can your refinery afford not to invest in its people?

Upskilling to Prevent Hidden Financial Leaks in Refineries

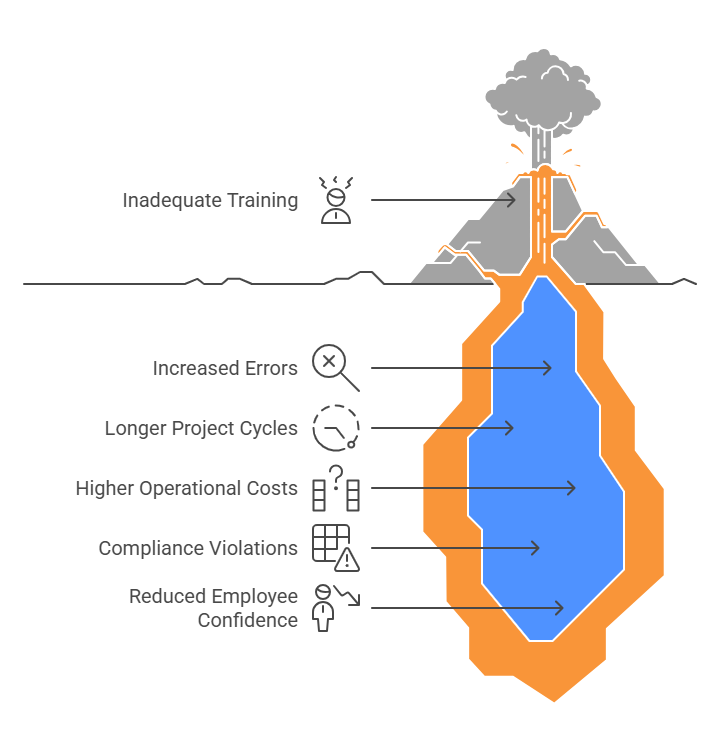

Inadequate training directly leads to increased errors, rework, and operational inefficiencies, all of which carry serious financial consequences. Not properly trained employees are more likely to make mistakes, slow down workflows, and require constant corrective actions. Over time, these issues drive operational costs through wasted materials, extended project timelines, and poor-quality outputs. Additionally, frequent errors can cause customer dissatisfaction, compliance failures, and even damage to high-value assets. Rather than being a minor inconvenience, the cumulative impact of poor training quietly drains profitability, making it a hidden but critical threat to the organization’s long-term success.

How Upskilling Reduces Costly Errors and Operational Inefficiencies

- Increased error rates leading to product quality issues and costly rework.

- Longer project cycles are due to slower task execution and corrections.

- Higher operational costs from wasted resources and repeated efforts.

- Greater risk of compliance violations, fines, and legal exposure.

- Reduced employee confidence and engagement are further hurting performance.

OMS quantifies avoidable losses by modeling cost-per-error scenarios, comparing trained vs. untrained teams, and projecting long-term savings from targeted upskilling investments.

Upskilling for Sustainable Productivity and Profitability Gains

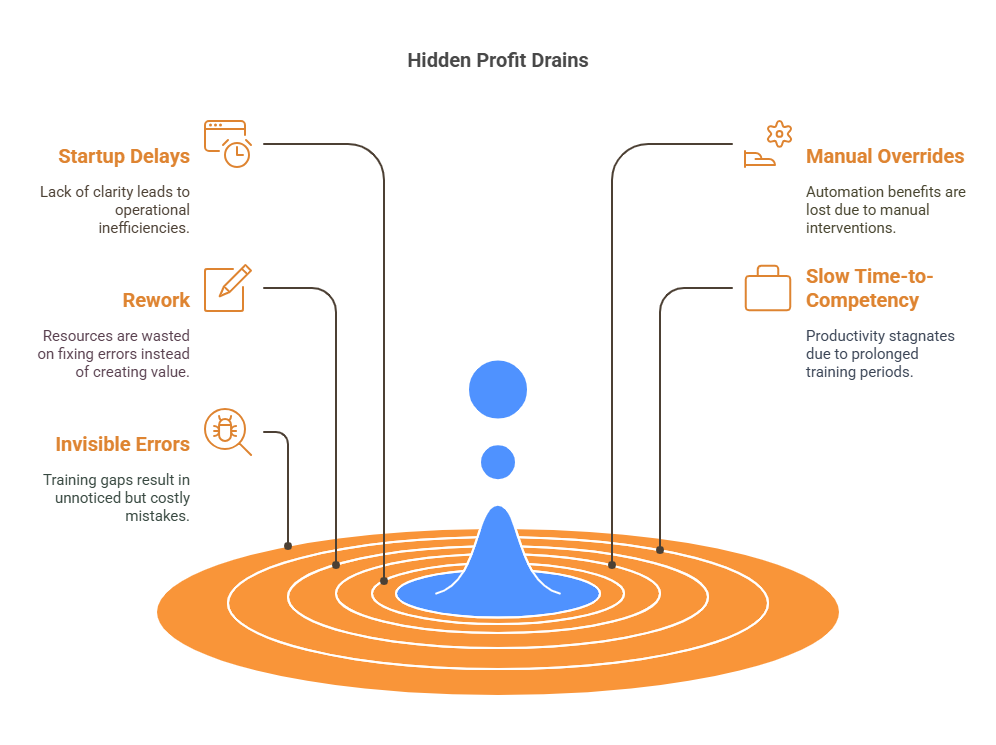

Beyond the immediate costs of operational errors, inadequate training leads to pervasive but less visible drains on productivity. Research from eLearning Industry highlights that companies with undertrained workforces experience prolonged downtimes, higher rates of rework, and sluggish operational cycles—all severely impacting profitability.

Upskilling to Reduce Downtime, Rework, and Manual Overrides

- Extended Downtime During Startups and Shutdowns: A Poor understanding of procedures lengthens critical transitions.

- Higher Frequency of Manual Overrides: Undermining automated systems and introducing human error risks.

- Increased Rework Cycles: Due to incorrect first-time execution of critical tasks.

These “invisible” losses erode margins quietly but relentlessly, compromising financial results and operational stability.

OMS tracks time-to-competency by measuring faster startups, fewer manual overrides, and improved first-pass rates, directly linking training to productivity and profitability gains.

Upskilling as a Strategic Resilience Tool in Refinery Operations

In the high-cost oil and gas refining world, CFOs carefully check every physical investment for its return on investment (ROI) and risk. In the same way, workforce development should be treated with equal importance. After all, innovative training programs can bring real returns by strengthening operations, helping get more out of assets, and protecting profits, just like significant equipment investments.

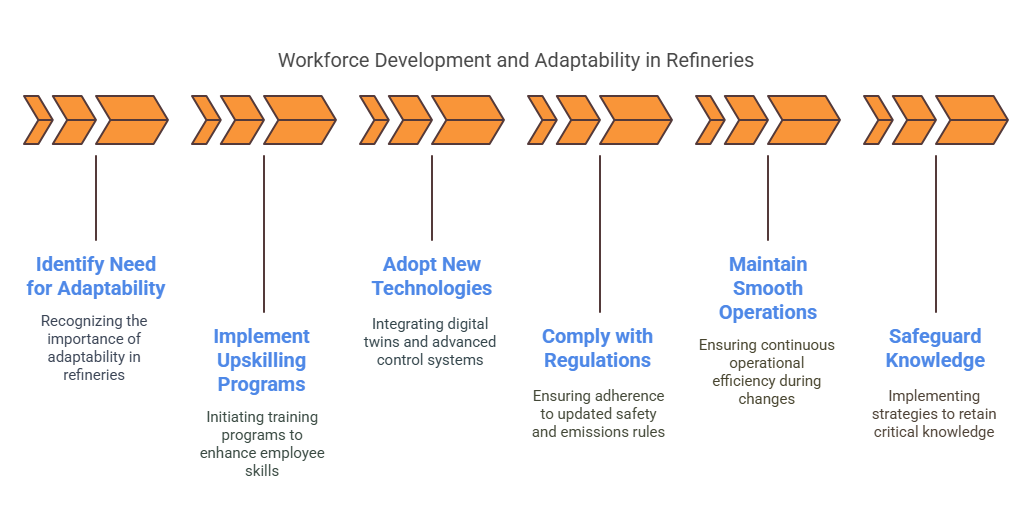

Today, refineries face fast-changing technology, market ups and downs, and new regulations. Because of this, employees who can quickly adapt to new tools, systems, and rules are key to keeping the business strong. According to research from Valamis, focused upskilling programs help companies react faster and handle outside pressures better, which helps protect their revenue.

So, how prepared is your workforce to keep pace with change?

How Upskilling Enables Faster Tech Adoption and Compliance

- Fast Adoption of New Technologies: Digital twins and advanced control systems.

- Quick Compliance with New Regulations: Like updated safety and emissions rules.

- Keeping Operations Running Smoothly: Even during workforce changes or market shifts.

OMS safeguards knowledge with scenario-based training, regular proficiency assessments, and targeted retention of critical roles to ensure operational resilience and sustained performance.

Upskilling to Maximize Asset Performance and Equipment Lifespan

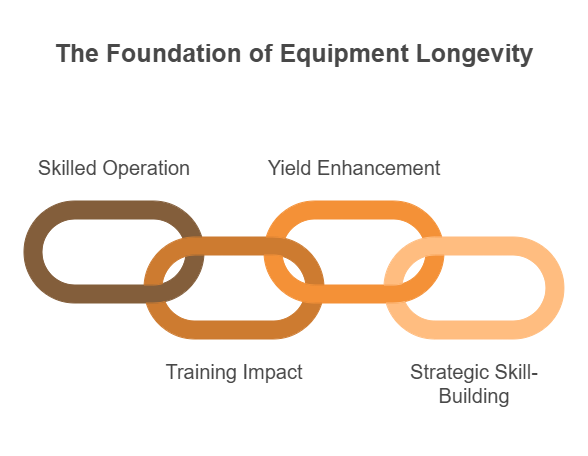

In a refinery, even the most advanced equipment—like turbines, distillation units, and tank systems—is only as good as those operating it. Employees who aren’t adequately trained can easily underuse or damage these high-value assets, leading to lower efficiency, faster wear and tear, and expensive downtime. Research from the Training Industry shows that investing in employee skills is key to getting the best performance from your equipment.

So, are you giving your team the tools to protect and maximize your most valuable assets?

Linking Upskilling to Asset Strategy and ROI

- Extended Equipment Lifespan: Through proper operation and preventive maintenance.

- Enhanced Process Yields: By optimizing production settings and minimizing variability.

- Safer Operations: Reducing wear-and-tear and avoiding catastrophic failures.

OMS integrates training with asset strategy by focusing on critical systems, high-ROI equipment, and maintenance best practices. This ensures teams maximize upgrades and performance while turning workforce development into a key operational and financial value driver.

Upskilling to Avoid Financial Risks and Regulatory Penalties

In refinery operations, the absence of a strategic training agenda erodes efficiency and exposes the organization to severe financial and legal risks. Compliance violations, workforce turnover, and escalating replacement costs are the “silent killers” of profitability that companies can no longer afford to ignore.

How Upskilling Prevents Compliance Violations and Legal Exposure

Failure to adhere to stringent safety and environmental regulations has steep financial consequences. Regulatory bodies like OSHA, EPA, and state agencies impose fines that can reach millions of dollars for non-compliance, not to mention the reputational damage and operational shutdowns triggered by serious infractions.

Inadequate training is a root cause of many compliance breaches, resulting in:

- Safety Violations: Mishandling hazardous materials, unsafe operational practices.

- Environmental Infractions: Non-compliance with emissions standards or spill containment protocols.

- Audit Failures: Gaps in documentation, reporting, and procedural adherence.

Each incident incurs direct fines, often increasing insurance premiums, legal settlements, and costly downtime.

OMS embeds compliance into daily operations with refresher modules, audit-ready training, and scenario drills—minimizing risk and ensuring smooth, regulation-ready refinery performance.

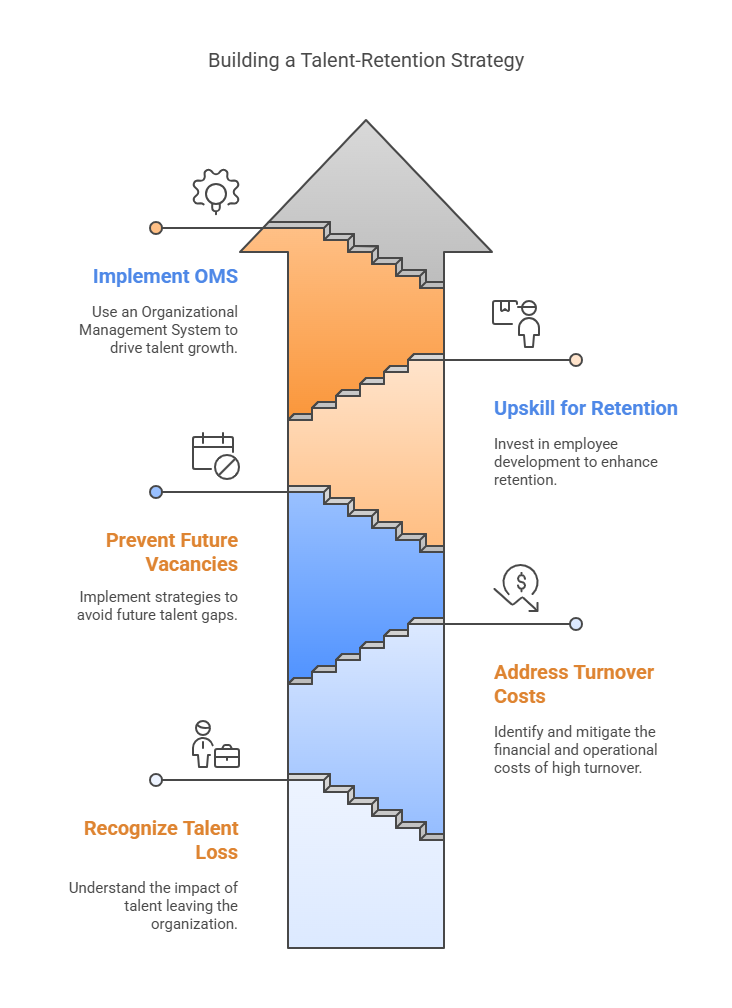

Using Upskilling to Reduce Turnover and Retention Costs

A less visible but equally dangerous cost of neglecting training is the impact on employee retention. Research shows that a lack of career development opportunities is one of the primary drivers of voluntary turnover, and replacing skilled refinery workers can cost 100% to 150% of their annual salary.

The operational consequences of turnover include:

- Loss of Institutional Knowledge: Eroding decades of operational insight.

- Reduced Operational Efficiency: Increased error rates and downtime during onboarding phases.

- Higher Recruitment and Training Expenses: Prolonged vacancies and retraining new hires.

OMS tackles retention by creating a culture of growth and engagement. It offers clear role growth pathways, skill recognition programs to validate expertise, and training that builds confidence through mastery. This approach boosts employee engagement, preserves critical skills, stabilizes operations, and cuts replacement costs.

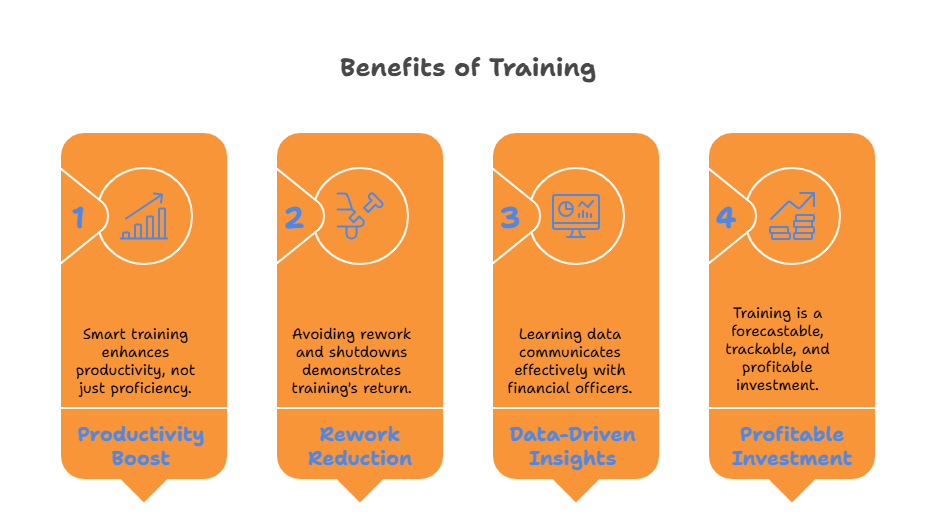

Upskilling as a Predictable Investment, Not an Overhead Expense

Many organizations still mistakenly classify training as an operational overhead rather than recognizing it as a strategic investment with predictable, measurable returns. In the manufacturing and refining sectors, where operational efficiency, regulatory compliance, and agility are critical, properly structured training programs have a direct and quantifiable impact on business performance.

Calculating ROI from Upskilling: Methods That Matter

When approached strategically, training costs can be forecasted with high accuracy and tied directly to measurable outcomes. Research from SHRM indicates that organizations investing effectively in employee development experience significantly improved profitability and productivity.

Key methodologies for calculating training ROI include:

- Productivity Gains: Measuring output improvements post-training.

- Error and Rework Reduction: Quantifying cost savings from fewer operational mistakes.

- Downtime Avoidance: Tracking reductions in unplanned shutdowns or slowdowns.

- Margin Improvements: Monitoring enhancements in yield and throughput efficiency.

OMS makes it easy to measure training impact with CFO-friendly dashboards, real-time tracking against operational KPIs like downtime and margin per barrel, and customizable reports by asset, department, or skill. By turning learning data into clear financial insights, OMS ensures training investments are managed as carefully as any major capital project.

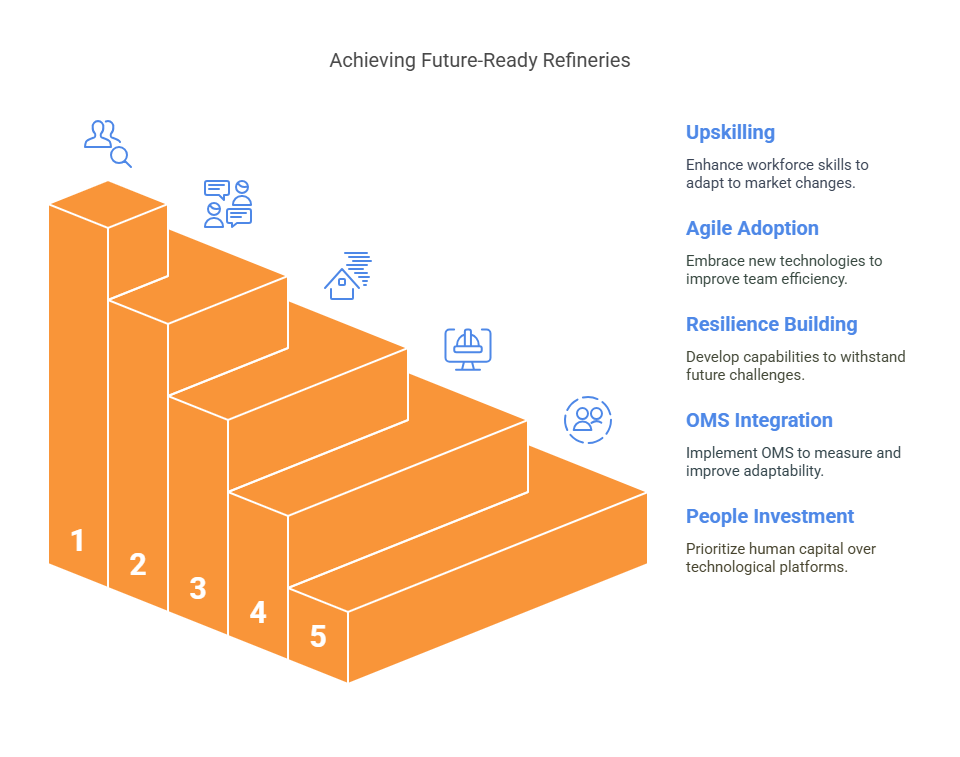

Upskilling Drives Agility in Uncertain Markets

The refining sector faces an unprecedented pace of change—from shifting energy markets and regulatory reforms to technological disruptions. Organizations that can adapt rapidly not only survive but thrive. Upskilling enables employees to respond effectively to new challenges and seize emerging opportunities.

According to the World Economic Forum, companies prioritizing upskilling develop a resilient, future-ready workforce capable of navigating market volatility and evolving customer expectations.

How Upskilling Equips Teams for Change and Innovation

- Faster Adoption of New Technologies: Advanced analytics, predictive maintenance tools, and digital operations platforms.

- Enhanced Responsiveness to Market Dynamics: Quick realignment of production strategies or process parameters.

- Stronger Competitive Positioning: Ability to deliver higher value to customers faster than less agile competitors.

OMS drives organizational agility with its “Readiness to Change” framework, which uses baseline assessments to gauge adaptability, microlearning sprints to quickly build targeted skills, and change readiness metrics to track progress. This proactive approach helps refineries pivot fast—whether facing new technologies, regulations, or market shifts—without missing a beat.

Upskilling Is the Business Case—Not Just a Budget Line

Strategic training is not a perk—it is a fundamental business driver. Companies can achieve substantial long-term value by linking training investments to operational resilience, compliance assurance, asset optimization, and workforce agility.

Final OMS Integration

OMS transforms traditional training approaches into high-impact, CFO-friendly performance initiatives by:

- Making Learning Measurable: Every training dollar is linked to tangible business outcomes.

- Designing Modular Programs: Allowing flexible, targeted development pathways based on operational priorities.

- Turning Cost Centers into Value Generators: Repositioning workforce development as a core pillar of margin protection and competitive advantage.

Strategic upskilling is not optional but mission-critical in the high-stakes oil and gas refining world. Organizations recognizing and acting on this reality will be best positioned to lead the industry into a more resilient, agile, and profitable future.