7 Proven Steps to Accelerate Refinery Digitalization for Operational Success

Table of Contents

The refining industry is at a turning point. Beyond the global energy transition, digital technologies offer tangible ways to improve efficiency, safety, and environmental performance. But fundamental transformation goes deeper than adopting new tools—it requires rethinking how refineries operate from the ground up. This blog provides a practical playbook for future-proofing refinery operations through innovative, scalable, and sustainable digital strategies. It focuses on actionable steps that deliver measurable results, not years from now, but starting today. Whether modernizing legacy systems or building new capabilities, the goal is clear: drive meaningful impact through thoughtful, technology-enabled operational change.

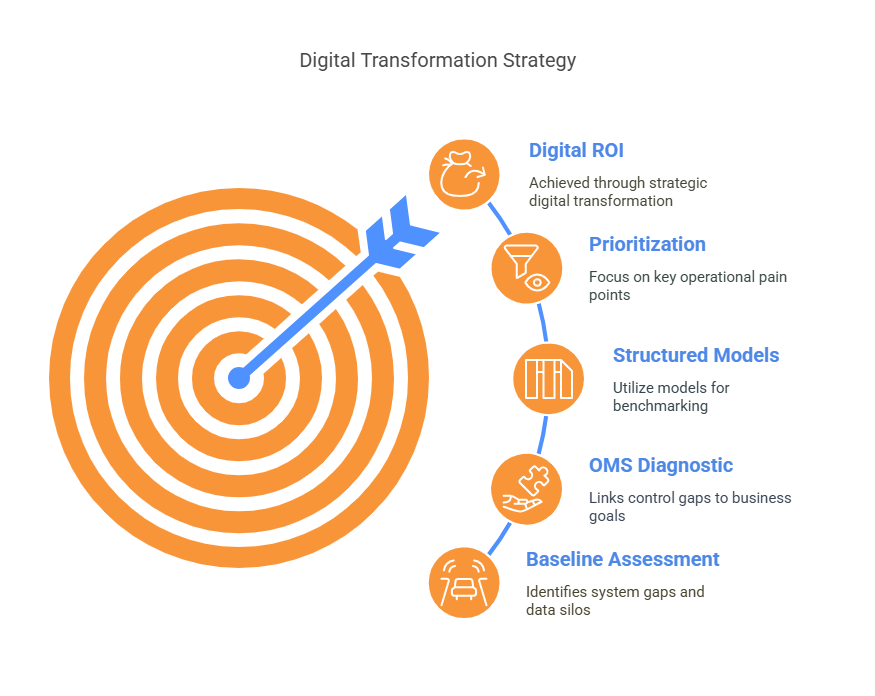

Step 1 – Set the Foundation for Refinery Digitalization

Conduct a Digital Readiness Assessment for Refinery Digitalization

Before starting any digital transformation, refineries need a clear picture of where they currently stand. And that means more than just listing the technologies they use. It requires a strategic map of existing systems—everything from control platforms and data historians to instrumentation and automation layers.

The reality? Many plants still depend on outdated, disconnected systems, which create data silos and make it hard to get a full view of performance. Understanding this baseline is the first—and most critical—step toward making smart, targeted improvements that move the needle.

Structured frameworks like AVEVA’s Digital Maturity Model can help assess readiness across automation depth, data integration, and decision support. But maturity isn’t just about systems—it’s also about people and processes. Input from operations, maintenance, planning, and IT teams often surfaces hidden challenges and missed opportunities that technical audits overlook.

OMS helps refineries take this crucial first step with a Digital Maturity Diagnostic built specifically for offsite operations and control architecture. It goes beyond spotting technical gaps—it looks at how they affect performance, emissions, and reliability. More importantly, it connects the findings to business goals so leaders can prioritize the right upgrades, delivering real, measurable value.

- Map systems. Hear from teams.

- Align tech readiness with operational reality.

- Let data—and people—guided the roadmap.

By laying this groundwork, refineries clarify their current position and create a strategic lens through which to evaluate every future digital initiative.

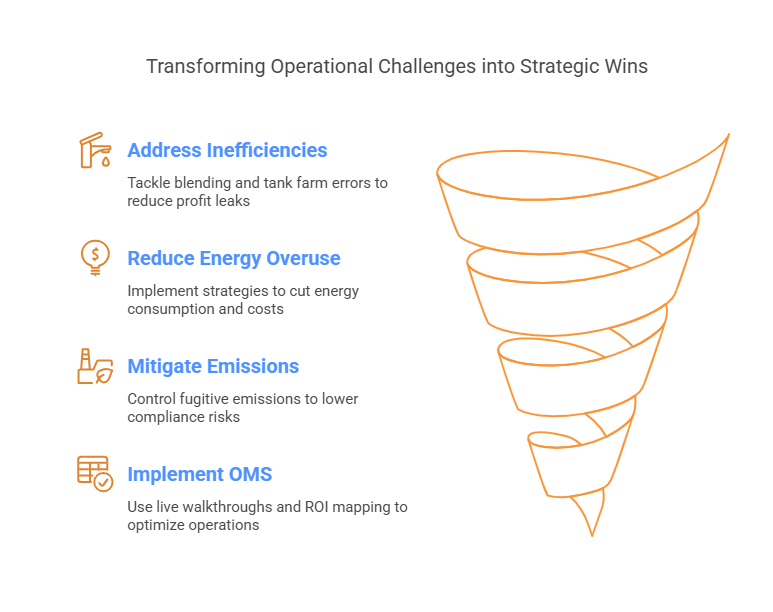

Step 2 – Identify High-Impact Areas for Refinery Digitalization

Not all pain points are created equal. A targeted approach means prioritizing those directly affecting margins, emissions, safety, or unplanned downtime.

Common focus areas include:

- Inefficiencies in blending systems

- Errors in tank farm operations

- Fugitive emissions management

- Overuse of steam, power, or nitrogen

According to KBC’s Digitalization in Refineries, identifying and addressing these weak points can unlock millions in value when connected with the right digital tools.

Use Value Mapping to Target Pain Points Through Refinery Digitalization

OMS helps clients map operational pain points (e.g., product giveaway, tank movement delays) to digital interventions with proven ROI. Through collaborative workshops and live process walkthroughs, OMS helps transform operational nuisances into strategic value drivers.

Step 3 – Build the Business Case for Refinery Digitalization

Use ROI Modeling to Prioritize Refinery Digitalization Projects

Not every digital project delivers equal impact, especially in capital-intensive environments like refining. Prioritizing initiatives based on return on investment (ROI) ensures that decisions are technically sound and financially strategic. Quick wins such as predictive maintenance, energy dashboards, or blending control upgrades often deliver high returns with minimal capital outlay. For example, AspenTech reports that predictive maintenance can reduce expenses by 20% and cut unplanned failures by 40%. But ROI isn’t just about savings—decision-makers should also weigh payback period, deployment ease, and alignment with ESG or compliance goals. Projects that improve emissions reporting or operational safety often secure broader buy-in from legal, finance, and sustainability teams.

OMS supports this with a refinery-specific ROI modeling framework that accounts for real workflows, implementation complexity, and business impact. These tools bridge the gap between engineering priorities and executive goals, making digital transformation measurable, justifiable, and scalable.

- Evaluate cost savings and strategic alignment.

- Include payback period, complexity, and ESG impact.

- Identify quick wins with high operational ROI

- Justify blending and energy upgrades with real data.

- OMS modeling speaks both operational and financial language

- Make smarter digital bets—grounded in value, not hype

Step 4 – Align Refinery Digitalization with Strategic and ESG Goals

In today’s ESG-driven landscape, digital transformation must boost margins and support broader goals.

Every digital project must be aligned with your key performance indicators (KPIs), whether reducing CO₂ emissions, enhancing operator safety, or improving product yield. As DigitalRefining’s Business Case for Digitalisation points out, this alignment ensures funding and cross-functional buy-in from finance, compliance, and safety teams.

Build KPI-Aligned Digital Roadmaps for Refinery Success

OMS helps refineries design and sequence digital projects that boost performance and sustainability metrics. The roadmap ensures that transformation efforts drive measurable ESG impact while aligning with regulatory commitments and strategic business goals.

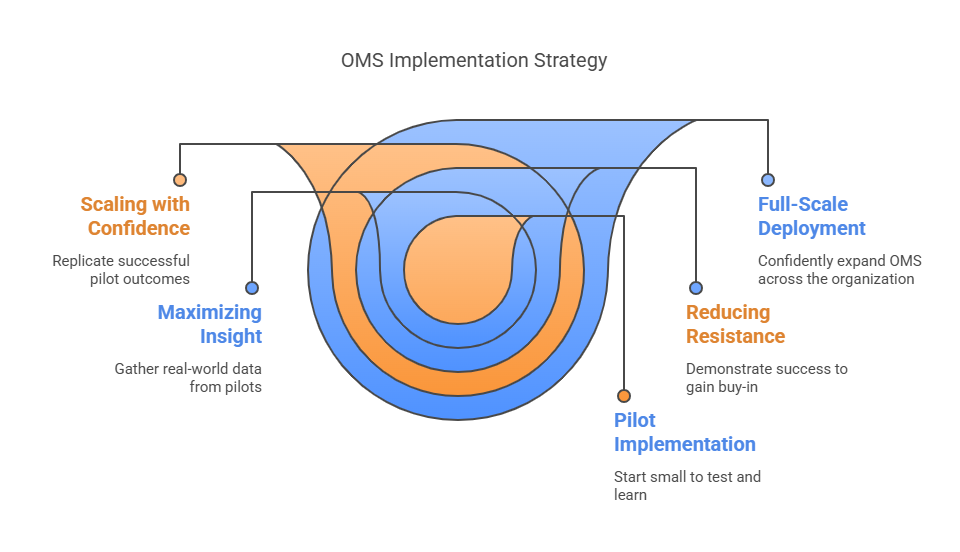

Step 5 – Start Small and Scale Refinery Digitalization

Pilot Programs for Refinery Digitalization with Measurable KPIs

Digital transformation doesn’t have to begin with sweeping, high-risk overhauls. The most effective approach often focuses on starting small, proving value, and scaling. Piloting a digital solution in a specific unit, such as a crude distillation unit with blending inefficiencies, allows for real-time validation of performance indicators while minimizing operational disruption.

These controlled environments are testbeds for fine-tuning system architecture, gathering operator feedback, and resolving integration issues before a broader rollout.

- Emerson’s Refinery Digital Transformation Case Study highlights that successful pilot programs help build internal momentum, reduce change resistance, and accelerate department adoption.

- When done right, pilot programs are not just technical experiments—they’re strategic proof points that show how digital tools can deliver measurable improvements in safety, efficiency, and profitability.

- OMS specializes in designing and executing scalable pilot programs with clearly defined KPIs from day one.

- These pilots are intentionally narrow in scope but deep in insight, allowing stakeholders to evaluate real-world performance before committing to full-scale deployment.

- Once validated, OMS transforms these pilots into replicable templates that streamline implementation across multiple units or refinery sites.

- This modular, pilot-to-scale approach ensures that each step in the transformation journey is data-driven, risk-mitigated, and aligned with strategic goals.

Step 6 – Upskill Teams for the Digital Refinery Workflow

A common myth in digital transformation is that upgrading means overhauling everything. In reality, the more innovative—and often more sustainable—path is to layer new digital capabilities onto existing infrastructure.

- Most refineries have invested heavily in Distributed Control Systems (DCS), SCADA, or PLC platforms. Replacing them outright is not only costly but often unnecessary.

- With the rise of edge computing, cloud-based analytics platforms, and middleware integration, it’s now possible to build a digital layer of intelligence that connects seamlessly with legacy systems.

- This hybrid architecture enables faster deployment, minimizes CAPEX, and avoids the operational disruptions that full system replacements often entail.

- Aramco’s Yanbu Refinery transformation is a standout example of this strategy, which uses clever layering instead of system rip-and-replace to achieve digital maturity.

Step 7 – Sustain Refinery Digitalization with Governance & Scalability

OMS embraces a non-disruptive, hybrid approach to digital integration, combining AI/ML models, soft sensors, and real-time simulators with your refinery’s existing control layers. This strategy ensures that your prior investments in control systems remain intact while unlocking new operational insight and decision-making speed levels. The result? More brilliant performance without system downtime.

Use Feedback Loops to Optimize Refinery Digitalization Over Time

Technology is only as powerful as the people who use it. As refineries evolve, so do the roles of their operators, engineers, and planners.

- The next generation of workflows will demand familiarity with dashboards and analytics tools and the ability to interpret data, simulate responses, and make informed decisions under pressure.

- Training needs to go beyond button-clicking and interface walkthroughs. It must be scenario-based, role-specific, and operationally realistic.

- Programs like Texas A&M–Corpus Christi’s Refinery Operations Course emphasize this shift. In it, digital acumen and plant know-how come together in simulated environments that reflect the true complexity of refinery operations.

- To meet this need, OMS offers a modular, simulation-driven eLearning platform explicitly designed for the refinery context.

- Every learner engages with role-relevant, scenario-rich training modules that mirror real-world operational challenges, from control room operators to long-term planners.

- This isn’t just training—it’s transforming workforce readiness for the digital refinery era.

Sustain Progress with Governance and Measurement

Create Feedback Loops for Continuous Improvement

Digital transformation doesn’t end at deployment—it evolves through refinement. For refineries to sustain long-term value, it’s critical to establish real-time feedback loops that track adoption, usage patterns, and performance outcomes.

This means going beyond static dashboards to monitor KPIs continuously, assess how tools are being used on the ground, and identify where interventions are delivering value or falling short. Non-performing tools must be improved, repurposed, or retired to maintain strategic focus and resource efficiency. As McKinsey’s report on AI-powered organizations emphasizes, sustained digital success hinges on responsiveness, not just implementation.

OMS Performance Tracking Tools

OMS enables this evolution through performance dashboards with embedded KPI benchmarking and usage analytics. Plant managers gain visibility into which digital tools drive impact, which need optimization, and how strategic plans should adapt. This capability ensures that digital transformation remains a living process, not a one-time event.

Plan for Versioning and Scalability

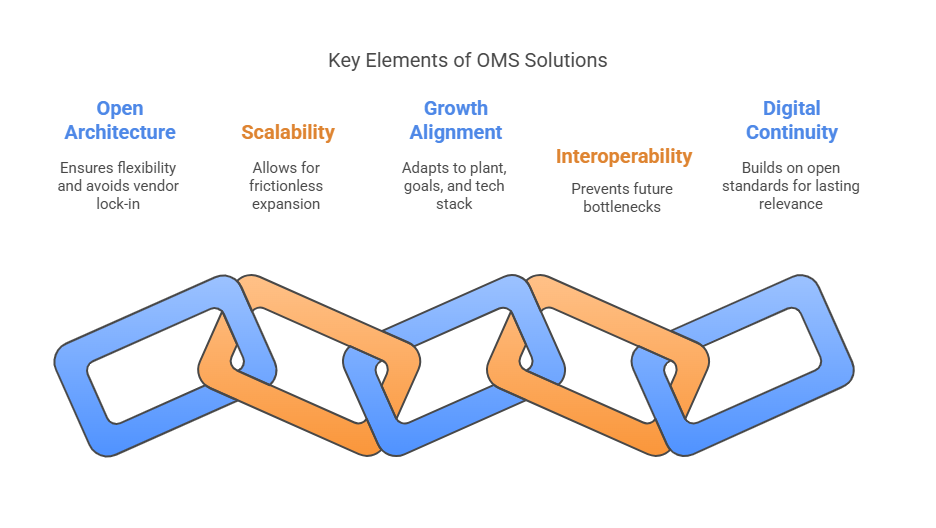

Future-proofing a refinery isn’t just about today’s performance—it’s about tomorrow’s adaptability. Digital ecosystems must be built on open, modular architectures that support upgrades, expansion, and third-party integrations without the friction of vendor lock-in or obsolete infrastructure.

Refineries can ensure the growth of their digital infrastructure by emphasizing interoperability, modularity, and scalability, whether scaling across units, integrating with logistics, or expanding to other plants. As the ARC Advisory Group outlines, open standards are the cornerstone of digital continuity.

OMS Future-Proof Architecture

OMS designs every solution with a standards-based, interoperable architecture that ensures seamless scalability across process units, multiple refineries, and even adjacent domains like distribution and supply chain. This approach empowers clients to build once and scale confidently.

Conclusion

The refinery of the future will not be defined by the most expensive technology but by the smartest strategy. Digital transformation isn’t about ripping and replacing—it’s about layering intelligence onto your existing foundation, enabling people to make faster, better decisions, and aligning every initiative with your long-term goals.

Refineries that follow a structured, feedback-driven roadmap—with clearly sequenced priorities, empowered teams, and flexible architectures—achieve operational efficiency and strategic agility.

With the right technology partner, digital transformation becomes more than a project—it becomes a performance engine. As the World Economic Forum’s Digital Transformation Initiative affirms, the actual driver of success is not complexity, but consistency. The future is already within reach for refineries ready to lead the next era of energy and efficiency.