Traditional blending systems heavily rely on physical analyzers, which are prone to delays, maintenance issues, and inaccuracies in real-time blending operations.

These limitations often result in suboptimal blending, higher costs due to quality giveaways, and inefficiencies in meeting stringent quality specifications

The AI/ML/FPBM-based less analyzer dependent blending system provides a revolutionary approach by leveraging advanced machine learning models and hybrid optimizers.

This patent-pending solution eliminates the need for physical analyzers, offering real-time prediction of blend qualities using historical and real-time data.

By optimizing the blend recipe and continuously predicting tank qualities, it ensures precise control, reduced quality giveaways, and improved operational efficiency.

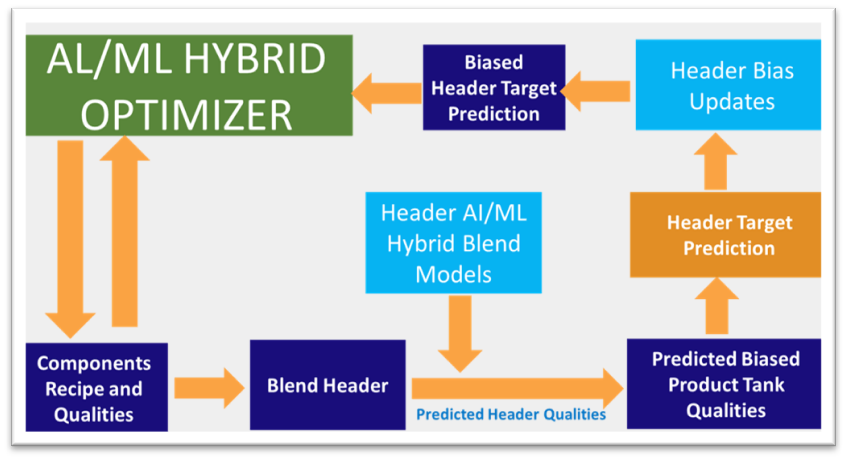

•Predicted Header Qualities

•Biased Header Target Prediction

•Predicted Biased Product Tank Qualities

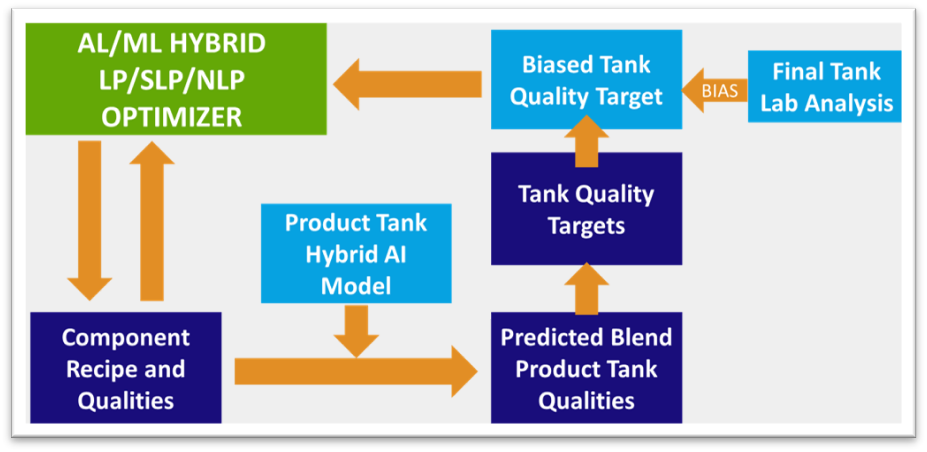

•Predicted Blend Product Tank Qualities

•Biased Tank Quality Target

•Final Tank Lab Analysis Integration

Catch wind of the latest technologies, strategies, and information to boost your business operations.