Background

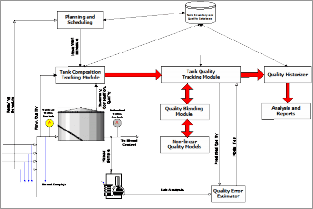

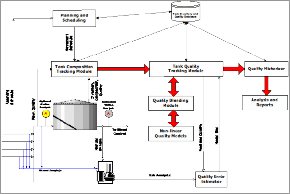

Every processing unit in a refinery or chemical plant requires the quality and quantity of its feedstocks stored in its tank farm. Although the inventory of products and stocks can be obtained online by implementing a combination of automatic Tank Gauging System (ATG) and Tanks Inventory Management Systems (gomsTIMS™), their qualities are not available online in real-time. Since there is a time lapse between the lab samples, its analysis and data entry, any quality dependent processing and control decisions are done on old quality values. Even online analyzers do not always solve the problem as they are installed either upstream of the tank or downstream of the processing unit.

A comprehensive Tank Quality Tracking System enables the online and near real-time availability of tank qualities to plant processing units and minimizes costly and time-consuming lab analyses of tank samples.

Figure – 1 gomsTQTS™ System Architecture

Applications

Tank Quality Tracking System (gomsTQTS™) can be used very effectively for:

- Products Blending

- Crude Blending

- Naphtha Blending

- Online control of process units

- Plant-wide planning and scheduling

- Process optimization

Benefits

- Reduction in man-power cost for sample collection & lab analysis

- Online optimization of process Units

- Reduction in capital Expenditure of online analyzers

- Online availability of Stock tank qualities for Blending

- Online Certification of tanks and blended product

- Minimization of off-spec or quality giveaway

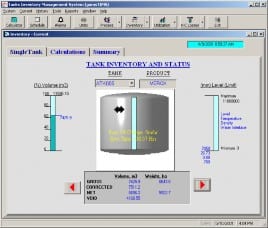

Composition Tracking

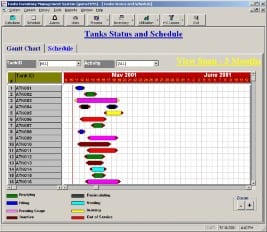

gomsTQTS™ provides a facility for composition tracking of any tank at all times. At any point of time the composition of the tank contents will be calculated using the data/information on flow rates of different components in the tank. This will lead to component wise consumption/requirements with respect to any tank or blend. The menu ‘Inventory/Tank Composition’ will show the Tank Composition details for a selected tank.

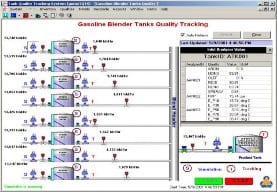

Figure – 2 Tanks Composition Tracking

Quality Tracking

The Tracking of Qualities will always be done for all the qualities that have been configured for tracking. This is done through continuously calculating the qualities of the tank contents using data from process interface and mathematical models. Thus, a lot of data is generated continuously. Every time a current set of data is generated, the previous set of data will be appended in the history table of the data. This data is analyzed and converted into proper information for the decision-making. This data can be retrieved either ‘Tank wise’ or ‘Product wise’.

Figure – 3 Quality Tracking for Gasoline Blender

Additional Capabilities

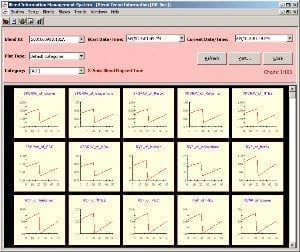

The system also has the following additional features:

- Quality calculator

- Reconciliation from lab or online analyzers

- Historizer

- Integrated Operator Training Simulators

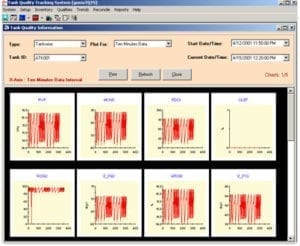

Figure – 4 Multi tanks quality trends

Features

- Online Tracking of tank composition and qualities

- Non-linear quality models for crude and finished products

- Lab analysis or online analyzers of tank source stream

- Inter-connection of tanks maintained for quality integration purpose

- In and outflows accounted for in the tank mass balance

- Tabular or graphical Historical Tank qualities

- Lab analysis of tank samples used for model bias corrections

- Integrated with comprehensive tank information management system and inline blending control systems

- Comprehensive reports and management

information system - Selection of Quality models and methods

- Online grouped and zoomed trend plots

- Configuration of online analyzer

- Manual or automatic lab data entry

- Online alarms

- Interfaces with tank gauging system, blenders, user access security

Economics

Economically, it is estimated an annual savings of $4,000-$5,000 for a reduction of 1 TQS number by online quality tracking system gomsTQTS™ where TQS = (Number of Tanks) * (Number of qualities analyzed /(sample-tank)) * (Number of Samples / tank).

System Requirements

Intel Core i7 or equivalent, 3+ GHz, 32GB RAM, 1TB+ HDD, CD ROM, 17”+ color monitor, Windows 7 and higher OS

Contact Information

Offsite Management Systems LLC

2003 Baker Estates Dr. Houston, Texas 77094, USA

Tel: +1-832-821-8001 Fax: 866-450-4035

Email: info@globaloms.com Web: www.globaloms.com

Copyright 2000-2015 Offsite Management Systems LLC. All rights

reserved. OMS™, OMS logo (Tri-circle Triangle), ”…Redefining

Excellence, gomsTQTS™ are trademarks of Offsite Management

Systems LLC, USA.