How Oil Price Volatility Drives the Need for Refinery Automation- Challenges, Roles, Benefits

Table of Contents

Oil price volatility is a reality that every refinery faces. One day, prices soar due to geopolitical tensions, and the next, they plummet because of shifting demand. How do refineries keep up?

The stakes are high—margins tighten, operational costs fluctuate, and regulations evolve. Yet, one thing remains constant: the need for efficiency. At Offsite Management Systems LLC (OMS), we work closely with refineries to navigate these challenges with innovative automation solutions. Whether optimizing fuel blending, integrating AI for predictive maintenance, or enhancing operational efficiency, automation is no longer a luxury—it’s a necessity.

But where should refineries start? This blog discusses the impact of oil price fluctuations and how automation can transform refining operations for long-term resilience.

Understanding Oil Price Volatility

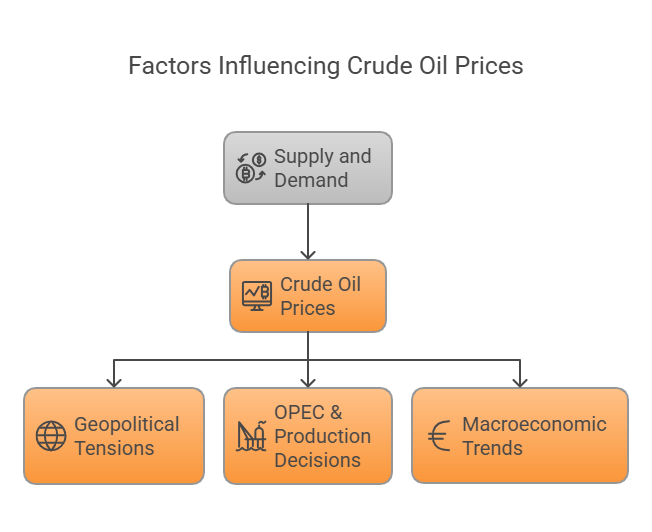

Oil prices are influenced by multiple factors, including:

- Supply and Demand: Shifts in production and consumption impact crude oil prices. (Investopedia)

- Geopolitical Tensions: Conflicts, trade sanctions, and instability in oil-producing regions create uncertainty.

- OPEC & Production Decisions: The Organization of the Petroleum Exporting Countries (OPEC) plays a crucial role in setting production quotas, affecting supply levels, and price stability (Ashling Partners).

- Macroeconomic Trends: Inflation, interest rates, and economic slowdowns affect oil demand and pricing.

For an in-depth understanding of these factors, refer to Oil Price Analysis: The Impact of Supply and Demand.

Challenges Faced by Refineries Due to Oil Price Volatility

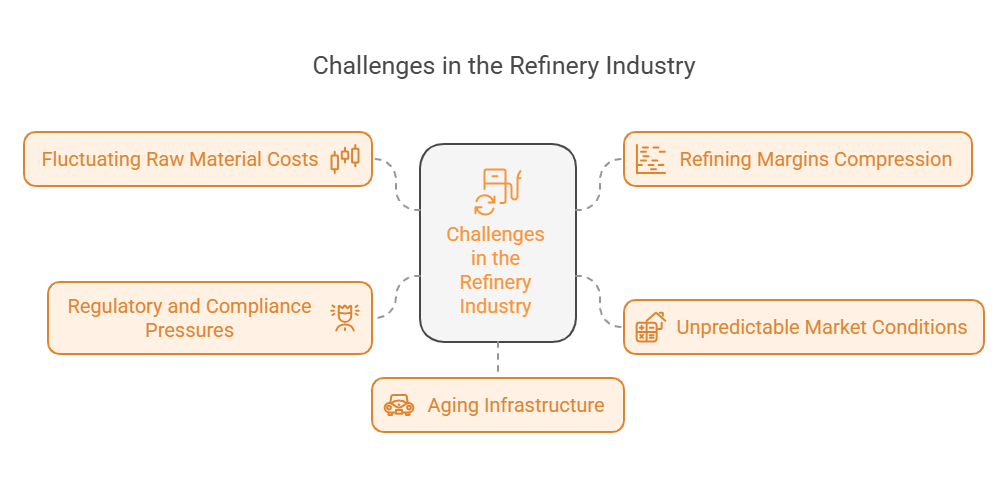

Oil price fluctuations directly impact refinery operations in several ways:

- Fluctuating Raw Material Costs: Since crude oil is the primary feedstock for refineries, price swings significantly affect operating expenses.

- Refining Margins Compression: When crude oil prices spike, refineries may struggle to maintain profitability unless they optimize production.

- Unpredictable Market Conditions: Volatile pricing makes long-term planning and investment decisions challenging.

- Regulatory and Compliance Pressures: Governments impose strict environmental and safety regulations that require continuous monitoring and adaptation (Ashling Partners).

- Aging Infrastructure: Many refineries operate with outdated equipment, making them less adaptable to changing market dynamics.

So, what’s the solution? Automation. But not just any automation—strategic, refinery-specific automation. That’s where OMS comes in.

The Role of Automation in Refinery Operations

Automation technologies can help refineries navigate price volatility and remain competitive. Here’s how:

1. Process Optimization with AI & ML

Integrating AI and ML in refinery automation has transformed how refineries manage operations. These technologies process vast amounts of real-time data, enabling predictive analytics, process optimization, and proactive decision-making. AI-driven systems improve refinery efficiency by enhancing forecasting capabilities, feedstock blending, and predictive maintenance. By leveraging AI and ML, refineries can minimize downtime, reduce costs, and maximize output quality, improving adaptability to oil price fluctuations. Advanced AI and ML algorithms analyze real-time data to optimize refinery operations, leading to:

- Better Forecasting: AI-driven predictive analytics help anticipate price fluctuations and adjust refining schedules accordingly (Investopedia).

- Efficient Feedstock Blending: AI enhances fuel blending, ensuring optimal product quality while minimizing costs.

- Reduction in Downtime: AI-based predictive maintenance prevents unexpected equipment failures, reducing operational disruptions.

At OMS, we develop custom AI models for feedstock blending, process control, and forecasting, ensuring that refineries:

✔ Optimize fuel blending while maintaining strict quality standards.

✔ Prevent unexpected failures with predictive maintenance.

✔ Adjust production schedules based on real-time market conditions.

A detailed discussion on AI in refining can be found at The Role of Automation in the Future of Energy for Oil & Gas.

2. Robotic Process Automation (RPA) for Back-Office Efficiency

Robotic Process Automation (RPA) is crucial in streamlining refinery back-office operations, reducing human error, and increasing efficiency. Refineries can improve operational speed and accuracy by automating repetitive tasks such as invoice processing, procurement, and regulatory reporting. With fewer manual processes, companies can allocate resources more effectively, ensuring that critical logistical and compliance-related tasks are handled with precision and minimal disruption, even in the face of volatile oil prices. RPA automates repetitive and time-consuming tasks such as:

- Invoice Processing and Procurement: Automating purchase orders and supplier contracts reduces costs.

- Regulatory Compliance and Reporting: Bots ensure accurate reporting and compliance with government regulations.

- Supply Chain Management: Automating logistics and tracking enhances inventory management, reducing waste.

At OMS, we help refineries integrate RPA into their existing workflows, ensuring smoother operations and cost-effective resource allocation.

3. Industrial IoT (IIoT) for Real-Time Monitoring

Adopting Industrial IoT (IIoT) in refineries redefines efficiency, safety, and performance monitoring. Refineries can track and analyze real-time operational data by integrating sensors and connected devices, improving decision-making and maintenance strategies. IIoT enhances safety by automating leak detection, enabling predictive maintenance, and optimizing energy consumption. This real-time oversight minimizes operational disruptions, reducing costs and ensuring that refineries adapt efficiently to fluctuating crude oil prices and market uncertainties. IIoT integrates sensors and connected devices to collect and analyze operational data. Benefits include:

- Improved Safety: Automated leak detection and monitoring enhance worker and environmental safety.

- Energy Efficiency: Smart sensors adjust energy usage based on demand, cutting operational costs (Ashling Partners).

- Predictive Maintenance: IIoT enables condition-based maintenance, reducing equipment failures and extending asset life.

At OMS, we help refineries integrate IIoT into existing systems, creating a smarter, safer, and more efficient operation.

4. Advanced Process Control (APC) for Precision Operations

Advanced Process Control (APC) is essential in refining operations, enhancing precision, efficiency, and consistency. APC systems utilize real-time data analytics to fine-tune processes, ensuring optimal production efficiency. Refineries can improve yields while maintaining consistent product quality and reducing energy consumption by dynamically adjusting variables such as temperature, pressure, and flow rates. With its ability to automate and refine critical operations, APC helps refineries stay competitive and resilient in a volatile oil market.

APC ensures that every variable in a refinery—temperature, pressure, flow rates—is dynamically optimized. With OMS’s APC solutions, refineries can:

- Optimized Production: Adjusting variables in real-time maximizes yield and efficiency.

- Consistent Product Quality: Automation ensures adherence to strict product specifications.

- Reduced Energy Consumption: Automated energy management minimizes waste and improves sustainability.

Benefits of Refinery Automation Amid Oil Price Volatility

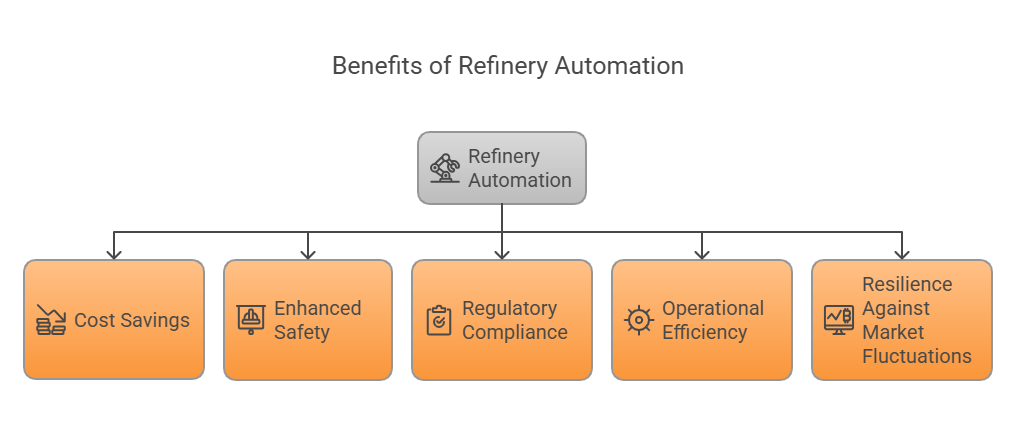

- Cost Savings: Lower operational and maintenance costs improve profit margins.

- Enhanced Safety: Automation reduces human exposure to hazardous environments.

- Regulatory Compliance: Digital tracking ensures adherence to evolving industry standards.

- Operational Efficiency: AI-driven automation optimizes resource utilization and minimizes waste.

- Resilience Against Market Fluctuations: Data-driven decision-making enables refineries to adapt quickly to changing oil prices.

How Oil Price Volatility Drives the Need for Refinery Automation: The OMS Perspective

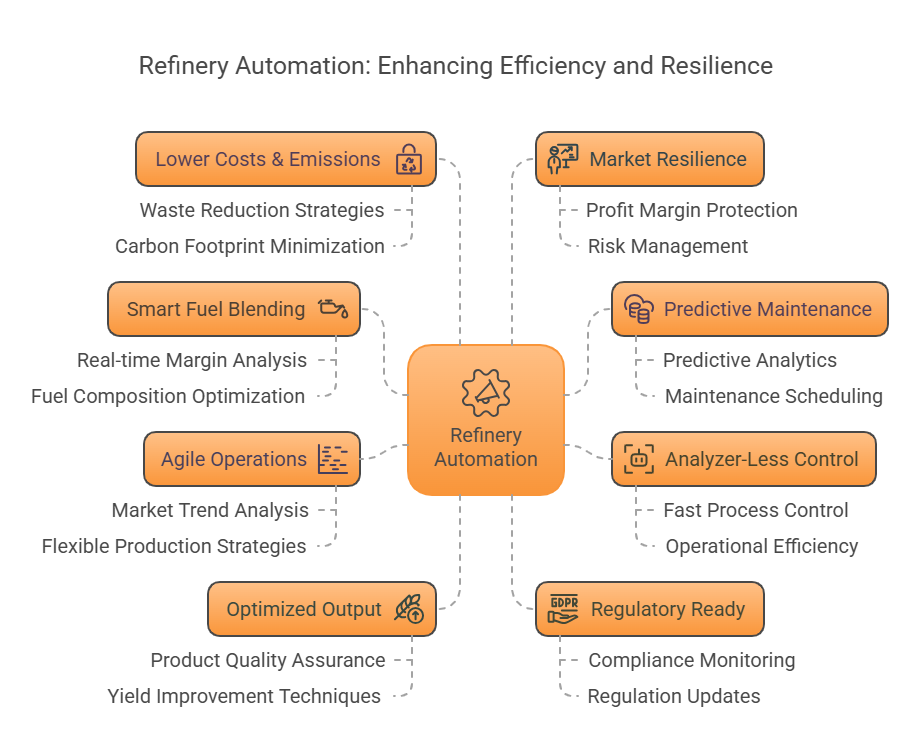

In an industry where oil price volatility remains a significant challenge, OMS is at the forefront of refinery automation, helping companies navigate market fluctuations with AI-driven fuel blending, ML-powered predictive maintenance, and analyzer-less hybrid models. By integrating FPBM hybrid modeling and intelligent process automation, OMS ensures that refineries can respond dynamically to crude price shifts, optimize production margins, and maintain regulatory compliance. As oil prices remain unpredictable, OMS’s solutions enable refineries to enhance efficiency, minimize operational costs, and reduce carbon emissions, making it a crucial player in shaping the future of energy sustainability. Through automation-driven innovation, OMS empowers refineries to achieve long-term stability and profitability despite fluctuating crude oil prices.

Refineries can thrive despite market uncertainty with OMS’s fuel-blending, predictive maintenance, and process control expertise.

Conclusion

Let’s face it—oil price volatility isn’t going away. But refineries don’t have to be at its mercy.

By implementing AI, ML, RPA, IIoT, and APC, refineries can take control of their operations, reduce costs, and enhance sustainability.

For additional insights, explore:

- The Role of Automation in the Future of Energy for Oil & Gas

- Oil Price Analysis: The Impact of Supply and Demand

- How AI and ML Are Transforming Refinery Operations

Embracing automation is no longer optional—it is essential for the future of refining in a volatile energy market.