FOR IMMEDIATE RELEASE

August 16, 2019

ENROLL TODAY: www.oms-elearning-academy.com

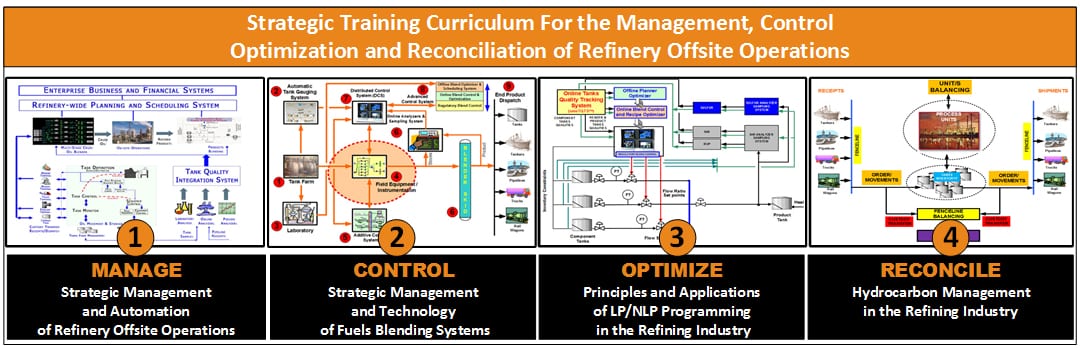

OMS eLearning Academy Offers 20+ Refresher and Extensive online courses for learning to Manage, Control, Optimize and Reconcile Refinery Offsite Operations.

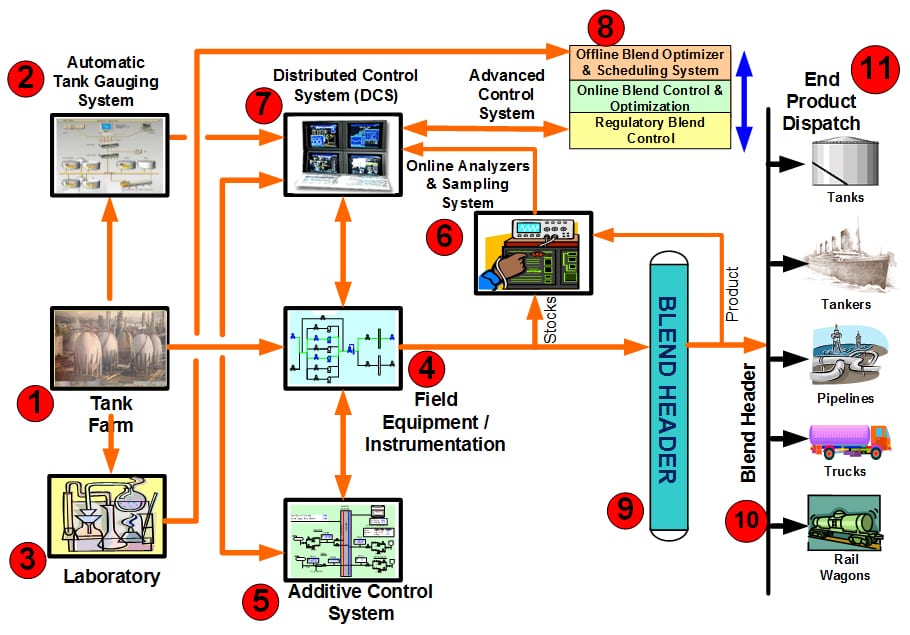

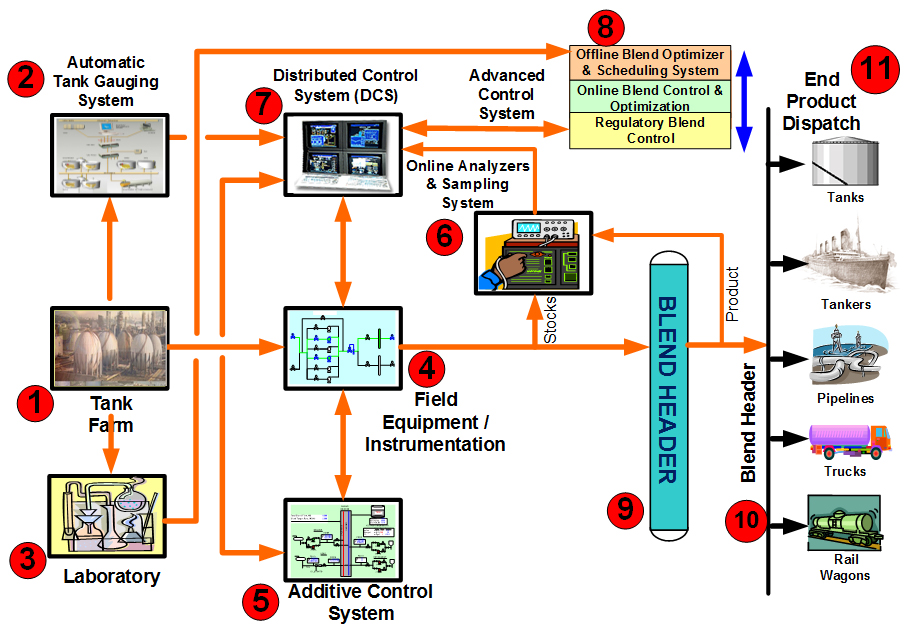

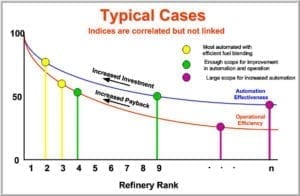

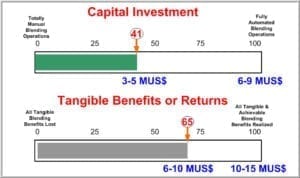

Houston, Texas, August 15, 2019 – Offsite Management Systems LLC (OMS) has launched their “OMS eLearning Academy” to offer online courses for the downstream oil Refinery Offsite Operations. The academy offers 20+ refresher and extensive courses to learn how to Manage Infrastructure, Control manufacturing, Optimize production, and Reconcile hydrocarbons. Downstream refineries produce 85-90% of its end products like gasoline, diesel, fuel oil etc. in offsite area peripheral to onsite process units. Inefficient and sub-optimal production of these products can affect the refinery’s bottom-line. For example, a 100KB/day refinery can lose 2-3 M$/year in tangible benefits by merely selling gasoline just 0.1 octane above its grade Octane spec.

These courses are targeted at refinery executives, managers, engineers, and operators as well fresh engineering graduates and students, and vary in length from 2 hours to 25 hours of online learning to teach the latest in refinery technology and management strategies to regain lost tangible benefits. The first phase of the academy is a refresher course with twelve topics worth 7+ hours of eLearning, a 60 mins free course on refinery technology and management strategy and many overview videos. The academy will be launched in phases and will be completed with all 21+ courses by mid-2020. The format of the courses are in high quality audio-video with English/Spanish sub-titles and will award a completion certificate after passing a quiz and taking a survey. These courses can be taken anywhere, anytime and on any device.

OMS eLearning Academy courses cost about 25-30% of similarly publicly offered courses and would save refineries millions of dollars per year in costs for training their staff. Dr. Suresh Agrawal, Founder & CEO, has 30+ years’ experience in the industry as executive and technical management with international companies like Exxon, ABB, etc. and has deployed many start-of-the art automation systems in refineries world-wide. He has taught these courses, for both public and private audiences for 25+ years and has earned a reputation for the prime content, as well as the interactive and stimulating presentations. Refining and related business professionals will be able to take advantages of his online courses and not be constrained by schedule and budget as with publicly held training events.

A few testimonies about the courses taught by Dr. Agrawal speaks for itself

“I have not attended any training course before which is so methodical, exceptional, rich in topics and presented excellently. I learned a lot about fuels blending in this course, thanks to the instructor. — Sergio Carvajal – IST corporation, Bogota”.

“The course was very interesting as I could relate the refining and auto industry problems and challenges in terms of fuel quality specifications and ways to meet them economically. — Jay Cummings, GM”

If you would like more information about this topic, please contact Dr. Suresh at: email s.agrawal@oms-elearning-academy.com.