The Silent Backbone of Refineries: Why Offsite Operations Deserve More Attention

Table of Contents

The Invisible Backbone of Refinery Success. In the energy and refinery industries, offsite operations often go unnoticed. Yet, these behind-the-scenes units—like blending, storage, utilities, and logistics—are essential to keeping a refinery running smoothly. The problem? They rarely get the same attention, resources, or training as core, on-site operations.

But in an industry where performance, precision, and safety are everything, overlooking offsite operations isn’t just a minor oversight—it’s a serious risk.

That’s where we come in. At OMS eLearning Academy, we believe it’s time to shift the mindset. Supporting offsite teams isn’t just a nice-to-have; it’s a strategic must. With the proper training and tools, these teams can make a significant impact on overall efficiency and reliability.

So in this blog, let’s unpack why offsite operations deserve more focus—and how modern learning platforms like OMS are helping refineries make that shift.

Offsite Operations and the Downtime Dilemma in the Energy Industry

Hidden Costs of Undertraining Unplanned downtime doesn’t just happen—it builds up quietly through small inefficiencies, lack of preparedness, and knowledge gaps. Often, these gaps arise from undertrained off-site teams working with outdated processes or unclear procedures. According to McKinsey, the most productive companies outperform their peers by 150%—not because they have more resources, but because they operate more efficiently. They run leaner, more innovative teams and adopt forward-looking maintenance strategies that keep them ahead of the curve. Even a minor mistake in one part of the supply chain can delay production, increase costs, and reduce overall throughput. In a competitive market, those hidden costs quickly add up.

OMS helps teams proactively eliminate downtime before it starts.

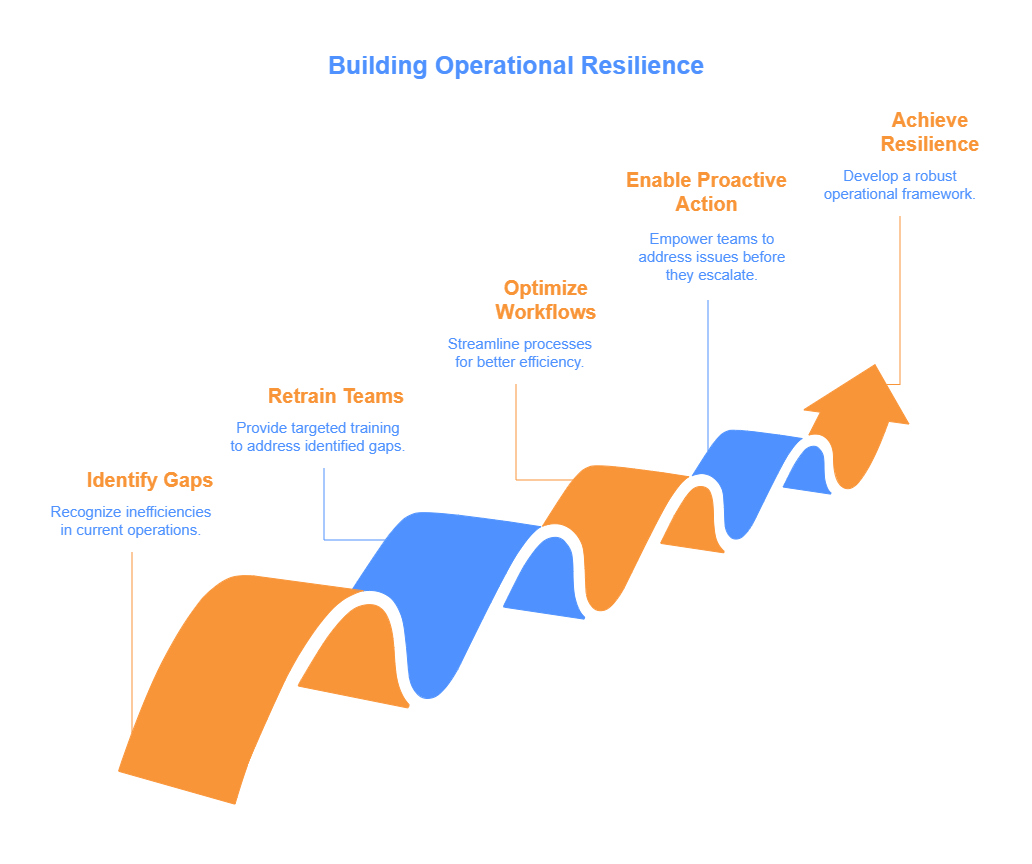

Our training programs streamline workflows and retrain personnel with performance-first learning, improving day-to-day efficiency and operational reliability. With OMS, downtime becomes the exception, not the rule.

In fact, can the Energy Industry Prevent Downtime with Better Training?

At OMS, the answer is a resounding yes. By equipping teams with the right skills and strategies, organizations can shift from reactive problem-solving to proactive performance, protecting their operations against costly interruptions.

Why Offsite Operations Are Still Overlooked in Refineries

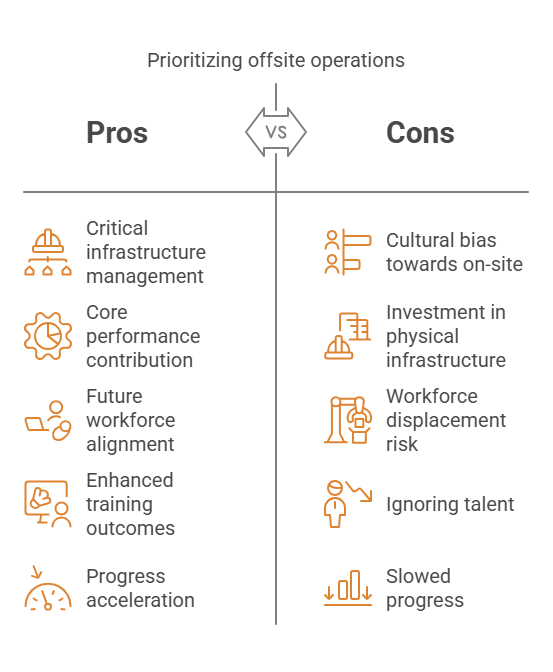

Why Offsite Still Gets Ignored Despite their importance, offsite operations often exist in the shadows of larger refinery priorities. There’s still a strong bias toward traditional, on-site operations. This cultural mindset makes remote work and virtual learning seem less valuable, even when the data says otherwise. According to EY, up to 30% of the oil and gas workforce could be displaced by 2040 due to the impact of automation and digitization. Yet many companies continue to invest more in physical infrastructure than in people, especially off-site personnel. Offsite teams manage critical infrastructure and contribute to core performance metrics. Ignoring them not only overlooks talent, but it also slows progress.

At OMS, we shine a light on these blind spots. Our platform validates and elevates off-site roles by aligning training outcomes with operational key performance indicators (KPIs). We help shift mindsets from outdated views to a forward-looking approach that sees off-site training as essential, not optional.

How Offsite Operations Training Can Prevent Safety Risks

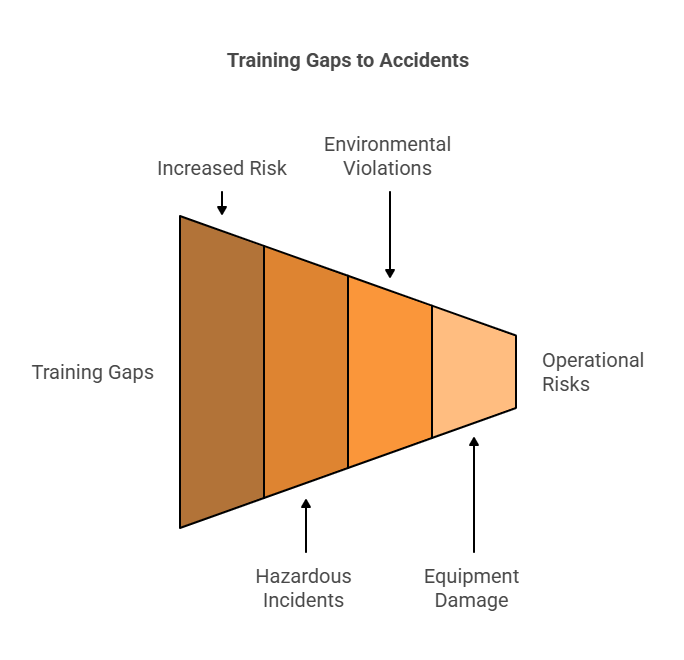

Training as Risk Prevention: Workplace Safety Starts with Training—and When Offsite Teams Don’t Receive Continuous, High-Quality Education, the Whole Operation Is at Risk. A small error during tank gauging or steam trap monitoring can quickly lead to hazardous incidents, environmental violations, or equipment damage. OSHA links 40% of industrial accidents to training gaps, and in refining, those gaps are often preventable. The American Petroleum Institute (API) emphasizes the importance of structured training for inspections, equipment handling, and auditing. Yet, many refineries still fall short on recurring training for off-site teams.

OMS turns safety into a proactive practice. Through mobile-first, role-specific modules, we keep off-site workers engaged and prepared. Our platform helps operators build the confidence and expertise to prevent issues before they escalate into emergencies.

Remote Work and the Rise of Digital Offsite Operations

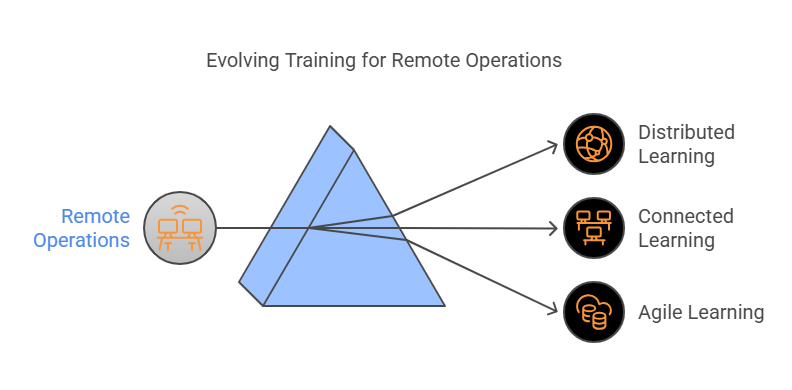

Remote is the New Core. Remote Operations Centers (ROCs) have redefined off-site work. Today, critical functions such as monitoring, adjustments, and inspections are often conducted digitally, sometimes from thousands of miles away. Norway’s Remota, for example, uses ROCs to control offshore ROVs and conduct inspections from shore. This shift demands a parallel evolution in training. Relying on occasional, centralized training sessions no longer aligns with the way work is done. Learning must be as distributed, connected, and agile as the teams it supports.

That’s why OMS acts as a refinery’s remote learning center. We deliver centralized training to decentralized teams, offer predictive upskilling, and make learning measurable and effective. With our platform, offsite operations aren’t isolated—they’re empowered, aligned, and always up to speed.

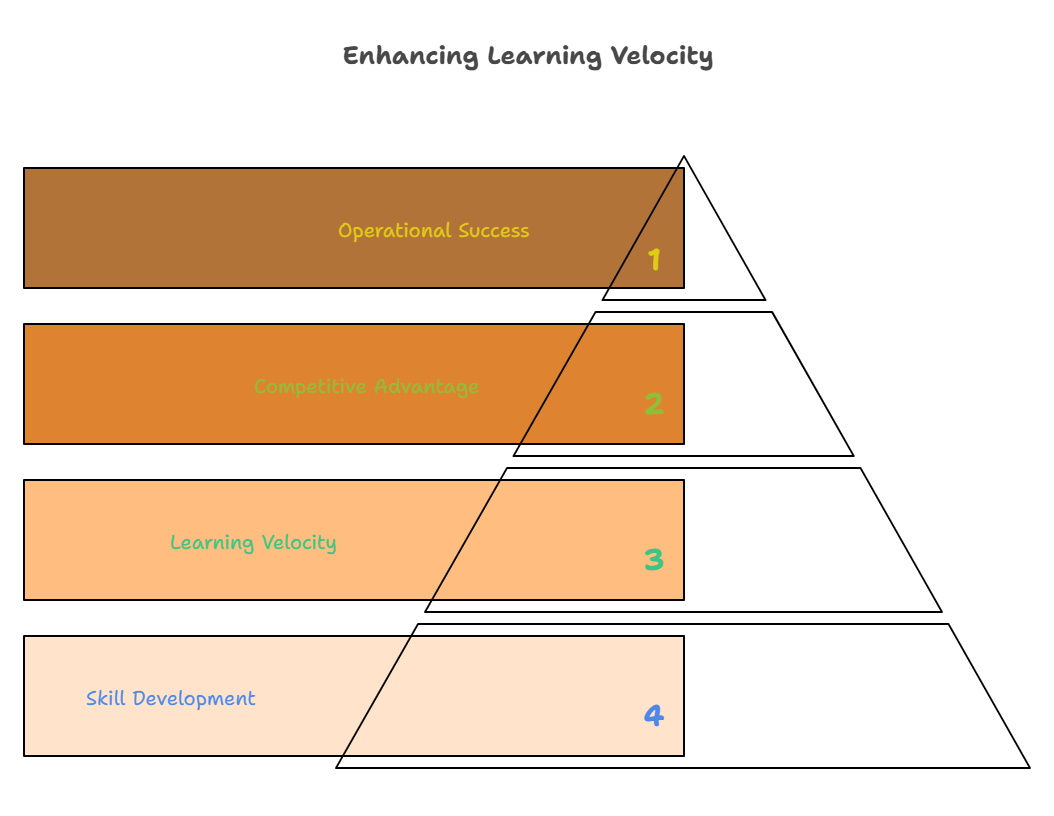

Learning Velocity: The New KPI for Offsite Operations Excellence

Your New Operational KPI In a fast-changing environment, the speed at which employees can learn and adapt is as important as what they know. That’s where the concept of “learning velocity” comes in. It’s a measure of how quickly a workforce can acquire and apply new skills to real-time challenges. McKinsey notes that companies prioritizing skill development, especially in cognitive, emotional, and problem-solving areas, are more resilient and adaptive. And in refining, where digital systems, automation, and AI are proliferating, earning impacts velocity directly translates to a competitive advantage.

OMS boosts learning velocity by tailoring education to individual roles, offering modular lessons, and ensuring knowledge sticks through real-world simulations. With us, training doesn’t just keep up—it stays ahead of the curve and delivers bottom-line results.

Measuring the Training Impact on Offsite Operations

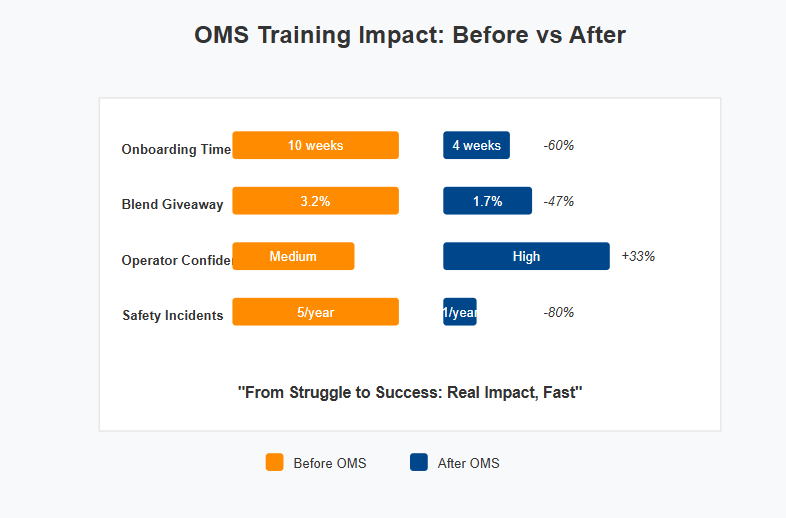

Let’s talk about real results. Carlos, a blending operator in Colombia, used to struggle with high blend giveaway every day. After taking just one OMS optimization course, his performance improved quickly, and giveaway dropped by 15% in just a few weeks. That’s real impact, fast. And Carlos isn’t the only success story. Across OMS clients, onboarding times have been reduced from 10 weeks to 4, blend variability has decreased by 18% in just three months, and teams report feeling more confident in their roles.

OMS training turns stories like Carlos’s into standard outcomes. Our platform delivers consistent, measurable improvements across operations, reducing cost, enhancing safety, and boosting morale.

Why Training Is the Infrastructure for Scalable Offsite Operations

The Backbone of Transformation Training is often viewed as overhead, but in reality, it’s operational infrastructure. Companies that prioritize continuous learning consistently outperform their peers in terms of adaptability, compliance, and digital maturity. According to Bain’s Energy Transformation Roadmap, companies that embed learning into operations respond to disruptions three times faster. BCG’s Digital Operating Model series confirms that workforce development is central to achieving digital maturity.

OMS builds that infrastructure. Our training ecosystem supports refinery success through strategic, role-based education that scales with your needs. From foundational knowledge to advanced analytics, we integrate learning directly into your daily operations, enabling seamless integration of learning into your daily workflow.

Modernizing Offsite Operations Training for the Future of Refining

Let’s face it—yesterday’s training models can’t keep up with today’s high-tech, high-stakes refinery environments. If teams don’t have timely, flexible access to learning, performance, and safety, they suffer. Paper manuals and annual refreshers aren’t enough.

OMS modernizes refinery training with intelligent, on-demand learning that integrates seamlessly into daily operations. Our mobile-accessible, role-specific programs adapt to your workforce’s needs and your evolving processes. Learning becomes a continuous advantage, not a disruption.

Benchmarking Learning Maturity in Offsite Operations

| Capability | Traditional Refineries | Digital Leaders | OMS Advantage |

| Training Delivery | In-person, annual | Online, continuous | Modular, on-demand |

| Skills Tracking | Spreadsheets | Dashboards | Integrated analytics |

| Offsite Training | Minimal | Business-aligned | ROI-measured |

OMS bridges the gap, making training a strategic driver of operational excellence.

Driving ESG & Compliance Through Offsite Operations Learning

Our digital platform supports your broader sustainability and compliance goals by:

- Reducing emissions through paperless, virtual training

- Offering safety courses aligned with ISO/API standards

- Providing multilingual content for greater accessibility

Leadership Check-In: Ask Yourself

- Are operators getting training exactly when and where they need it?

- How closely does your training align with performance KPIs?

- Are you tracking how quickly your teams are upskilled?

Why Offsite Operations Deserve More Strategic Focus

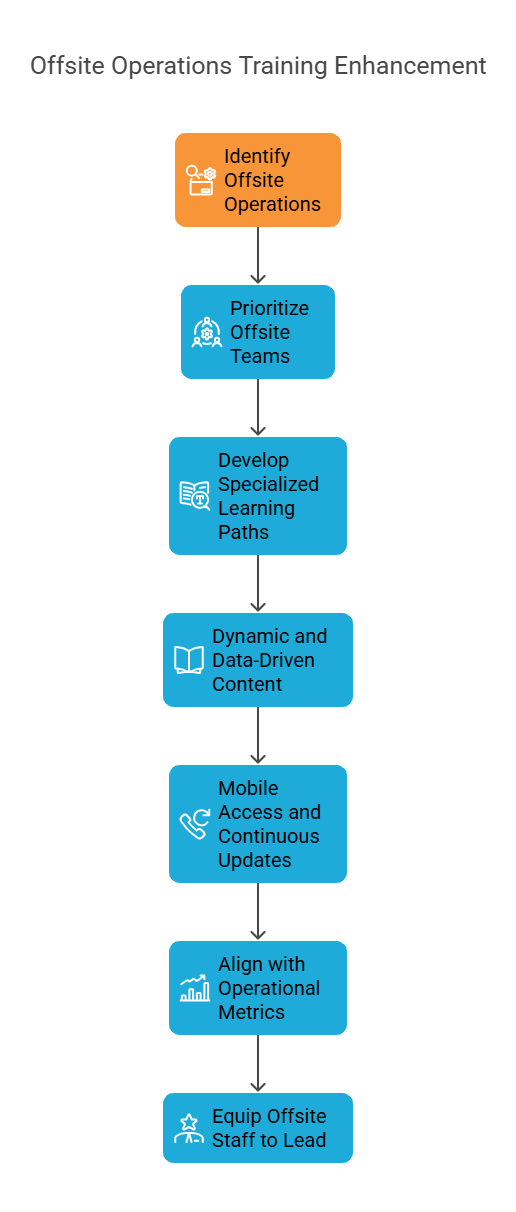

In most refineries, offsite operations—blending, logistics, utilities, storage—don’t receive the same training focus as core process units. OMS changes that.

We prioritize off-site teams with specialized learning paths tailored to their roles and challenges. Our content is dynamic, data-driven, and designed to build both competence and confidence in the field.

Through mobile access, continuous updates, and alignment with key operational metrics, offsite staff are not only included—they’re equipped to lead.

Conclusion: Offsite Operations Are Essential, Not Optional

Offsite operations are no longer the silent support act; they are central to the performance, safety, and agility of modern refineries. As the industry evolves, so must the approach to training these critical teams. Ignoring off-site operations is not just a missed opportunity; it’s a strategic vulnerability. By embracing role-specific, scalable, and digital-first learning solutions, organizations can unlock untapped potential, reduce downtime, and build a future-ready workforce. OMS eLearning Academy empowers refineries to turn training into a competitive advantage, making offsite excellence not only achievable but also essential. It is time to recognize that off-site operations aren’t optional; they are foundational.

Request a customized demo at

🔗 https://www.oms-elearning-academy.com/