Multi-periods, Multi-blends Non-linear Offline Blend Optimizer

Background

The planning of refinery blend products and the subsequent optimal control of the blending process has a significant immediate impact on refinery profitability and excess inventory. gomsPOFBlend™ off-line blending planning package considers production planning, inventory management, and the quality and value of blending components to optimize blending operations. It is a comprehensive package, which can be modularly integrated in a refinery’s MES structure.

Applications

Offline blend optimizer, planning and scheduling system (gomsPOFBlend™) can be used very effectively for:

- Single recipe generation for Gasoline, Diesel and Fuel oil products

- Multi-period blend planning for weekly inventory control and monthly production forecast

- Conducting blend studies for operational change modeling and LP verification

- Reblending to correct off-spec blends

- Backcasting to calculate blend models parameters and bias terms

- Analysis of compliance with EPA, CARB rules

- Blend Recipe Management and Automatic downloading of next blends recipes to online execution

Benefits

- Shift usage of more economical components

- Determine and exploit on-the-spot opportunities quickly

- Link refinery-wide planning to short term logistics

- Remove guesswork and artistry from blend planning

- Production of economically optimum product blends, thereby adding to refinery’s bottom line profitability

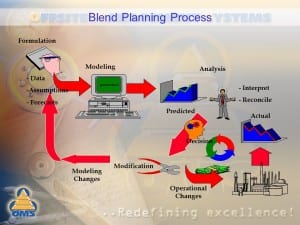

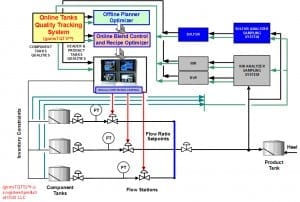

Figure – 1 OMS Blend Control, Optimization and Planning System Hierarchy

Figure – 1 OMS Blend Control, Optimization and Planning System Hierarchy

Features

- Basic

- Blending full range of gasoline grades, aviation jet to diesel fuel for distillate blends, and fuel oil blends.

- Multi-period planning with inventory control constraints.

- Number of multiple periods, feed-stock components, and product grades limited only by computer memory size availability.

- Can choose non-linear predictive methods “on the fly” for qualities

- Maximize profit, Minimize quality giveaway, Calculation only optimization Choices

- Determine the header targets for properties for an online system

- Advanced

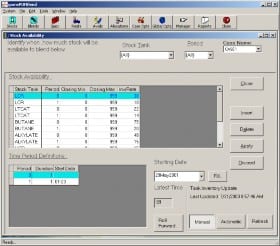

- Inventory Management – account for changing production and set time dependent limits

- Group Specifications – property constraints over groups of blends

- Heel Tracking – accounting for volume / qualities in tank already, for each use Component

- Pooling – simulate rundowns

- Generalized free-formatted linear and non-linear equations generation and management system (GAMS™)

- User Selectable options for multiple Correlations for 36 qualities

- 3 User definable blend qualities

- Extended

- Octane Blending Values – determine indices for use in LP’s

- Blend Property Control Interfaces- send recipes directly to on-line system

- Biases – add values to correct consistent errors

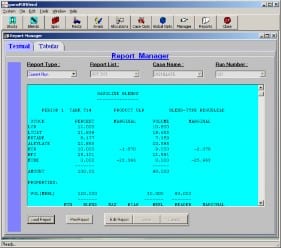

Figure – 2 Stock Availability Data Entry

Figure – 2 Stock Availability Data Entry

-

- Giveaway Ranges – ensure blend remains close to specification

- Infeasibility Control – recover from “impossible” situations, relax constraints until solution is found

- “Distress” Buy / Sell – provides indication of why problem won’t solve, calculate volume / quality needed to make an infeasible problem solve

- Environmental

- EPA RFG Models – blend to emission specifications, ignores extrapolations at iteration-level (may impact), report exactly as written

- CARB Phase II Predictive Model – report emissions, report acceptability

- Modeling and Correlations

- Preferred Recipe Penalties – encourages model to stay near a preferred Starting recipe

- Product Group Limits – volume constraints over groups of blends

- Product Group Relations – relate production of blends to each other

- User selectable built-in well proven correlations for over 40 properties for gasoline, diesel and fuel including EPA RGF and CARB models

- Optimal scheduling of multi-period blends

Interfaces

gomsPOFBlend™ allows direct interface with

- Regulatory and Online blend control and optimization system (gomsPONBlend™)

- Laboratory and Tank gauging data

- gomsTQTS™ for online tank quality tracking system.

- Blend Information Management System for feedback of model biases (gomsBIMS™)

Economics

Economically, it is estimated an annual savings of 750K–1.5MUS$ by Offline Recipe Optimization, and planning and Scheduling of blends.

System Requirements

Intel Core i7 or equivalent, 3+ GHz, 32GB RAM, 1TB+ HDD, CD ROM, 17”+ color monitor, Windows 7 and higher OS

Contact Information

Offsite Management Systems LLC

2003 Baker Estates Dr. Houston, Texas 77094, USA

Tel: +1-832-821-8001 Fax: 866-450-4035

Email: info@globaloms.com Web: www.globaloms.com

Copyright 2000-2015 Offsite Management Systems LLC. All rights reserved. OMS™, OMS logo (Tri-circle Triangle), ”…Redefining Excellence”, gomsTIMS™, gomsTQTS™, gomsPONBlend™, gomsPOFBlend™, gomsBIMS are trademarks of Offsite Management Systems LLC, USA.